Table of Contents

1

22

GROUP PROFILE

PRODUCT PRESENTATION

SOLUTIONS

REFERENCES

62

01

02

03

1.1 Standard Panel

2

2.1 Utility Scale

24

3.1 Utility Scale

64

1.2 Flexible/Light weight CIGS Panel

7

2.2 Distributed generation

27

3.2 Distributed generation

66

1.3 BIPV Panel

14

2.3 BIPV

29

3.3 BIPV

70

2.4 Flex Rooftop

34

3.4 Flex Rooftop

72

2.5 Vehicle and Yacht application

38

3.5 Vehicle and Yacht application

76

44

52

PRODUCT PRESENTATION

1.1

Standard Panel

1.1.1 MiaSolé CIGS Panel

1.1.2 Solibro SL2 CIGS Panel

1.1.3 Solibro SL2-F CIGS Panel

1.1.4 a-Si/uc-Si Panel

1.1.5 a-Si/Ge Panel

1.2

Flexible/Light weight Panel

1.2.1 MiaSolé FLEX CIGS Panel

1.2.2 Global Solar PowerFLEX™ CIGS Panel

1.2.3 Light weight Panel

1.3

BIPV Panel

1.3.1 Back electrode translucent Panel

1.3.2 Carved translucent Panel

1.3.3 Colored translucent Panel

1.3.4 Hollow Panel

1.3.5 Double-sided power Panel

1.3.6 Allotype Panel

1.3.7 Splice Panel

1.3.8 LOGO Panel

Chapter 01

PRODUCT

PRESENTATION

1.1

Standard Panel

Key product features:

Advanced technology, excellent quality, positive tolerance panels,

assurance for more generating capacity

1.1.1

MiaSoé CIGS Panel

1.1.2

Solibro SL2 CIGS Panel

MiaSoé MS SERIES -04

SOLIBRO SL2

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Standard Test Conditions (STC) :1000 W/m2 ,25℃ cell temperature,AM 1.5 G spectrum

Standard Test Conditions (STC) :1000 W/m2 ,25℃ cell temperature,AM 1.5 G spectrum

Power Class (W)

100

105

110

115

120

Minimum Power(+5/-0W)

100.0

105.0

110.0

115.0

120.0

MS150GG-04

MS155GG-04

MS160GG-04

MS165GG-04

MS170GG-04

MS175GG-04

Short Circuit Current (A)

1.68

1.68

1.69

1.69

1.69

Nominal Power (W)

150

155

160

165

170

175

Open Circuit voltage (V)

90.1

91.6

93.3

95.1

97.6

Current at PMPP (A)

1.46

1.49

1.52

1.54

1.56

Nomical Efficiency (% )

14.0%

14.5%

14.9%

15.4%

15.9%

16.3%

Voltage at PMPP (V)

68.5

70.5

72.4

74.7

76.9

Nominal efficiency (%)

≥ 10.6

≥ 11.2

≥ 11.7

≥ 12.2

≥ 12.8

Power Output Tolerance (W)

+5/-0

+5/-0

+5/-0

+5/-0

+5/-0

+5/-0

PERFORMANCE AT NORMAL OPERATING CELL TEMPERATURE(800W/m2 51±2℃,AM 1.5 G SPECTRUM)

Maximum Power Voltage (V)

19.2

19.6

19.9

20.3

20.7

21.0

Power Class (W)

100

105

110

115

120

Minimum Power(+5/-0W)

72.3

75.9

79.5

83.1

86.7

Maximum Power Current (A)

7.82

7.92

8.02

8.13

8.23

8.33

Short Circuit Current (A)

1.34

1.34

1.35

1.35

1.35

Output Circuit Voltage (V)

24.4

24.7

24.9

25.2

25.5

25.8

Open Circuit voltage (V)

82.0

83.4

84.9

86.5

88.8

Current at PMPP (A)

1.16

1.18

1.21

1.22

1.24

Short Circuit Current (A)

9.08

9.09

9.10

9.12

9.13

9.15

Voltage at PMPP (V)

62.1

64.0

65.7

67.8

69.8

TEMPERATURE COEFFICIENTS (AT 1000W/m2 ,AM 1.5 G SPECTRUM)

Maximum Series Fuse Rating (A)

25

Temperature Coefficient of ISC

Temperature Coefficient

α

±0.04

β

-0.29±0.04

(%K)

of VOC (%K)

Maximum System Voltage (V)

1000 / 1000

Temperature Coefficient of

γ

-0.38±0.04

PMPP (%K)

TEMPERATURE COEFFICIENTS

MECHANICAL SPECIFICATION

NOCT

45

Length

1190(+3/-1)mm

Width

789.5(+3/-1)mm

Temperature Coefficient of

-0.40

Pmpp (% / ℃ )

Height

7.3mm(+Junction box, 15mm)

Temperature Coefficient of Voc

Weight

16.5KG

-0.35

(% / ℃ )

Front cover

4 mm tempered low iron glass (ESG)

Temperature Coefficient of Isc

-0.003

(% / ℃ )

Back cover

3 mm float glass

Frame

None

MECHANICAL SPECIFICATION

Cell type

CIGS [Cu(In, Ga) Se2]

Length(mm)

1611

Junction box

Protection class IP 65, with 1 bypass diode (3A);66x54x15mm3

Width(mm)

665

Cable type

2.5mm2 Solar cable;(+)855(+30/-0)mm;(-)735(+30/-0)mm

Connector

MC4

Depth(mm)

7.5 / 28(including junction box)

PROPERTIES FOR SYSTEM DESIGN

Weight(kg)

18

Maximum System voltage (V)

1000 (IEC) / 600 (UL 1703)

Junction Box /Output Terminal

Maximum Reverse Curren (A)

5

2 corner connection boxes / MC4 type

Type

Wind / Snow Load (Pa)

2400

Maximum Load

Tested snow load: 5400N / m2

Safety Class

II

QUALIFICATIONS AND CERTIFICATES

Fire Rating

C

5 years warranty for materials and process;

Permitted module temperature

-40℃ bis +85℃

10 years 90%/25 years 80% warranty for power output

on continous duty

QUALIFICATIONS AND CERTIFICATES

IEC 61646, IEC 61730 (Application Class A), UL 1703 (Fire Class A)

EC 61646 (Ed. 2), IEC 61730 (Ed.1) application class A, UL 1703

The production site is certified according to ISO 9001 for Quality Management.

2

3

Chapter 01

PRODUCT

PRESENTATION

Key product features:

Key product features:

Stable and reliable quality, low-voltage, easy system design;

Simple installation, especially for small rooftop systems.

Safe and environmental-friendly.

1.1.3

Solibro SL2-F CIGS Panel

1.1.4

a-Si/uc-Si Panel

SOLIBRO SL2-F

a-Si/uc-Si Panel

ELECTRICAL PERFORMANCE

Panel Type

HNS-SD120

HNS-SD125

HNS-SD130

HNS-SD135

HNS-SD140

Standard Test Conditions (STC) :1000 W/m2 ,25℃ cell temperature,AM 1.5 G spectrum

ELECTRICAL PERFORMANCE(STC:1000W/m2,25℃,AM1.5)

Power Class (W)

100

105

110

115

120

Nominal Power (W)

120

125

130

135

140

Minimum Power(+5/-0W)

100.0

105.0

110.0

115.0

120.0

Maximum Power Voltage (V)

49

51

54

56

59

Short Circuit Current (A)

1.68

1.68

1.69

1.69

1.69

Maximum Power Current (A)

2.27

2.26

2.22

2.19

2.17

Open Circuit voltage (V)

90.1

91.6

93.3

95.1

97.6

Output Circuit Voltage (V)

67

69

71

73

75

Current at PMPP (A)

1.46

1.49

1.52

1.54

1.56

Short Circuit Current (A)

2.74

2.72

2.65

2.62

2.58

Voltage at PMPP (V)

68.5

70.5

72.4

74.7

76.9

Nominal efficiency (%)

≥ 10.5

≥ 11.0

≥ 11.6

≥ 12.1

≥ 12.6

ELECTRICAL CHARACTERISTICS(NOCT:800W/m2,45℃,AM1.5)

Performance At Normal Operating Cell Temperature(800W/m2 51±2℃,AM 1.5 G spectrum)

Nominal Power (W)

90

94

97

101

105

Power Class (W)

100

105

110

115

120

Maximum Power Voltage (V)

61

62

64

66

67

Minimum Power(+5/-0W)

72.3

75.9

79.5

83.1

86.7

Maximum Power Current (A)

2.26

2.25

2.19

2.17

2.14

Short Circuit Current (A)

1.34

1.34

1.35

1.35

1.35

Output Circuit Voltage (V)

44

46

48

50

53

Open Circuit voltage (V)

82.0

83.4

84.9

86.5

88.8

Short Circuit Current (A)

1.91

1.90

1.86

1.84

1.82

Current at PMPP (A)

1.16

1.18

1.21

1.22

1.24

TEMPERATURE COEFFICIENTS

Voltage at PMPP (V)

62.1

64.0

65.7

67.8

69.8

Temperature Coefficient of Pmpp (%

Temperature Coefficients (AT 1000W/m2

,AM 1.5 G spectrum)

-0.29

/ ℃ )

Temperature Coefficient of

Temperature Coefficient

Temperature Coefficient of Voc (% /

α

±0.04

β

-0.29±0.04

-0.32

ISC (%K)

of VOC (%K)

℃)

Temperature Coefficient of

Temperature Coefficient of Isc (% /

γ

-0.38±0.04

+0.07

PMPP (%K)

℃)

MECHANICAL SPECIFICATION

MECHANICAL SPECIFICATION

Length

1196.6(+1/-0.2)mm

Front cover

Low Iron Float Glass,3.2mm

Width

796.1(+1/-0.2)mm

Back cover

Tempered glass,3.2mm

Height

30mm

Materials

White EVA

Weight

18.1KG

Cell type

Tandem (a-Si/µc-Si)

Front cover

4 mm tempered low iron glass (ESG)

Junction Box Class

IP67

Back cover

3 mm float glass

Length (mm)

1300

Frame

Aluminum frame, black

Width (mm)

1100

Cell type

CIGS [Cu(In, Ga) Se2]

Depth (mm)

6.8 (Junction Box not included)

Junction box

Protection class IP 65, with 1 bypass diode (3A);66x54x15mm3

Area (m2)

1.43

Cable type

2.5mm2 Solar cable;(+)855(+30/-0)mm;(-)735(+30/-0)mm

Weight (Kg)

25

Connector

MC4

Cable Length (mm)

(+875) / (-565)

PROPERTIES FOR SYSTEM DESIGN

Connector

MC4 Compatible

Maximum System voltage (V)

1000 (IEC) / 600 (UL 1703)

PROPERTIES FOR SYSTEM DESIGN

Maximum Reverse Curren (A)

5

Maximum System voltage

1000V

Wind / Snow Load (Pa)

2400

Maximum Series Fuse Rating

6A

Safety Class

II

Power Output Tolerance

0/+5W

Fire Rating

C

Permitted module temperature on

Permitted module

-40℃ bis +85℃

continous duty

temperature on continous

-40℃ bis +85℃

duty

Load

2400Pa

QUALIFICATIONS AND CERTIFICATES

QUALIFICATIONS AND CERTIFICATES

EC 61646 (Ed. 2), IEC 61730 (Ed.1) application class A, UL 1703

CE、TUV Rheinland

The production site is certified according to ISO 9001 for Quality Management.

4

5

Chapter 01

PRODUCT

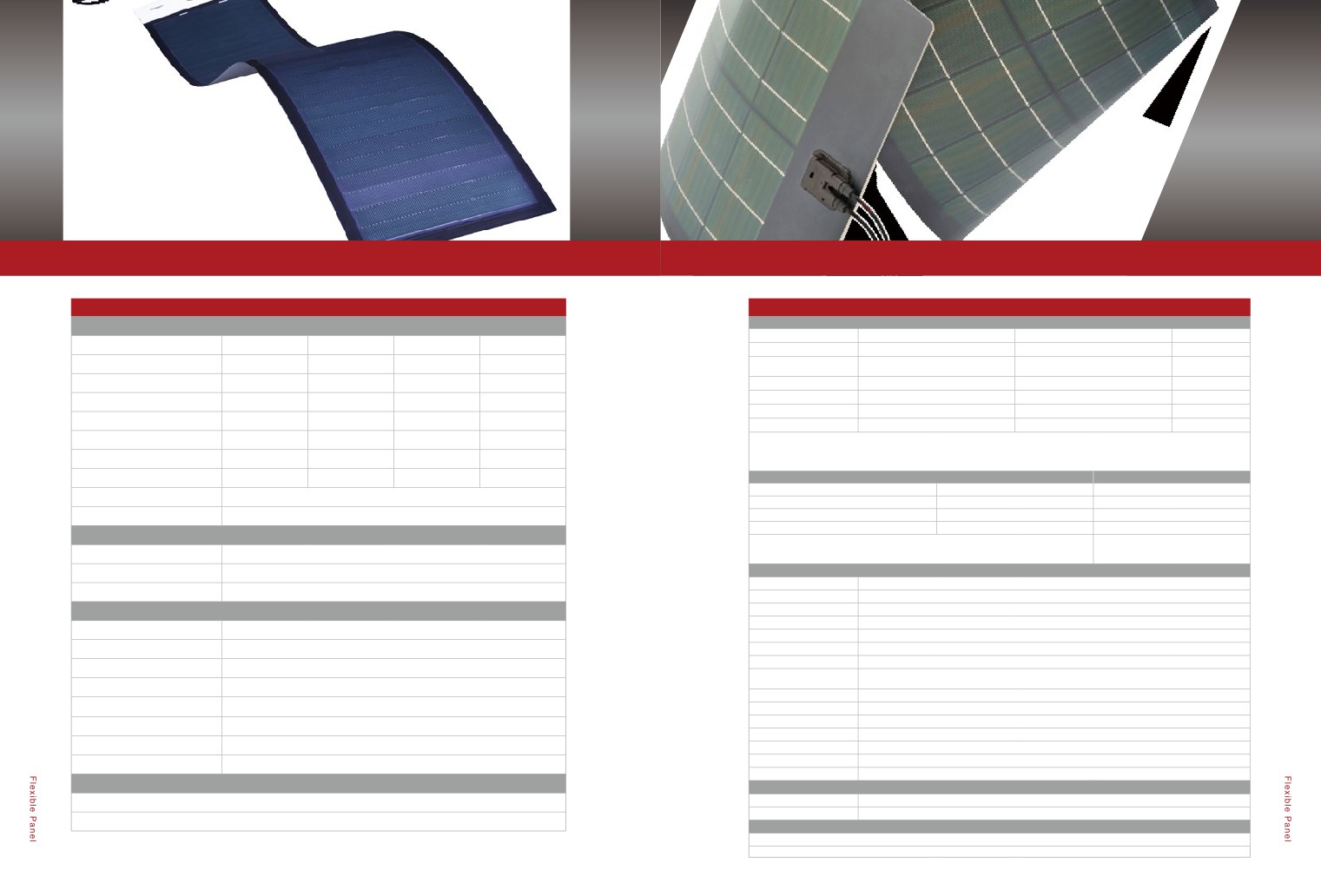

1.2

Flexible/Light weight Panel

PRESENTATION

MiaSolé FLEX SERIES

Key product features:

Lightweight, super thin, flexible, especially

suitable for light loads and curved roof;

Key product features:

Safe and reliable, can be directly attached,

High-temperature adaptability, good low-light

low installation costs;

generation performance.

Two widths panel options to choose from.

1.1.5

a-Si/Ge Panel

1.2.1

MiaSolé FLEX CIGS Panel

HNS-BT65B

MiaSoé FLEX-01W

PERFORMANCE

ELECTRICAL PERFORMANCE

Substrate

TCO Glass

FLEX-01 200W

FLEX-01 210W

FLEX-01 220W

FLEX-01 230W

PIN/PIN/PIN Triple-junction a-Si/Ge Cell, Glass-glass/J-box at back side non

Panel Type

Nominal Power(W)

200

210

220

230

see-through module

ELECTRICAL PERFORMANCE

Power Output Tolerance(W)

+10/-0

+10/-0

+10/-0

+10/-0

Maximum Power(W)

65

Maximum Power Voltage(V)

21.7

22.2

22.6

23.1

Maximum Power Voltage (V)

70

Maximum Power Current(A)

9.52

9.73

9.86

10.03

Maximum Power Current (A)

0.93

Open Circuit Voltage(V)

27.6

27.8

28.2

28.6

Output Circuit Voltage (V)

89

Short Circuit Current(A)

11.10

11.10

11.13

11.29

Short Circuit Current (A)

1.12

Module aperture area efficiency(%)

13.9%

14.6%

15.3%

16.0%

Power Output Tolerance(W)

0/+3

Maximum System Voltage(V)

1000 / 600

Maximum System voltage(V)

1000

Maximum Series Fuse Rating(A)

20

Maximum Series Fuse Rating(A)

2

TEMPERATURE COEFFICIENTS

TEMPERATURE COEFFICIENTS

Temperature Coefficient of Pmpp ( /

-0.45

Temperature Coefficient of Isc ( / ℃ )

0.02%

℃)

Temperature Coefficient of Voc ( / ℃ )

-0.20%

Temperature Coefficient of Voc ( / ℃ )

-0.36

Temperature Coefficient of Pmpp ( / ℃ )

-0.19%

Temperature Coefficient of Isc ( / ℃ )

-0.003

MECHANICAL SPECIFICATION

MECHANICAL SPECIFICATION

Length(mm)

1245

Length(mm)

1710

Width(mm)

635

Width(mm)

999

Height(mm,Junction Box not included)

9.7

Thickness(mm,Maximum at J-Box)

17

Weight(kg)

18.6

Weight (Module without adhesive)

4.2

(kg)

Area(m2)

0.79

Weight / Area(kg/m2)(Module

2.47

Junction box Type

Back connecting boxes

without adhesive)

Junction Box Class

IP68

Thickness of Junction Box(mm)

20

Junction Box Class

IP67

Cable Connections

MC4 Compatible

Cable Length(mm)

450

Cell Type

CIGS

Materials

PVB

QUALIFICATIONS AND CERTIFICATES

Front cover

3.2mm TCO

5 year workmanship; 5/10/25 year power output

Back cover

6.0mm Semi-tempered/ Tempered glass

UL1703,IEC61646,IEC61730(Application Class A)

6

7

第

章

01

产品介绍

Global Solar Power FLEX Series

Key product features:

Lightweight, super thin, flexible, especially suitable

for light loads and curved roofs;

Safe and reliable, can be directly attached, low

installation costs;

Three lengths panel options to choose from.

1.2.2

Global Solar PowerFLEX™ CIGS Panel

MiaSoé FLEX-01N

Global Solar PowerFLEX™(90/100W)

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Capacity rating

Pmax

100W

90W

FLEX-01 60N

FLEX-01 65N

FLEX-01 70N

FLEX-01 75N

Tolerance of Pmax

%

+/-5%

+/-5%

Nominal Power(W)

60

65

70

75

Module aperture area

%

12.7%

11.4%

efficiency

Power Output Tolerance (W)

+5/-0

+5/-0

+5/-0

+5/-0

Rated voltage

Vmpp

17.8V

16.5V

Rated current

Impp

5.6A

5.4A

Maximum Power Voltage(V)

21.6

21.7

22.3

22.8

Open circuit voltage

Voc

23.3V

22.0V

Maximum Power Current(A)

2.93

3.17

3.25

3.32

Short circuit current

Isc

6.4A

6.3A

Open Circuit Voltage(V)

27.1

27.6

27.9

28.3

Note 1: Standard Test Conditions (STC): Cell Temperature at 25° C; Solar irradiance intensity of 1000 W/m2; AM1.5 solar reference spectrum

(ASTM E892)

Note 2: Average efficiency is calculated using the 0.79 m2 aperture area of the module

Short Circuit Current(A)

3.62

3.70

3.70

3.73

Note 3: Electrical parameters are +/-10% unless stated otherwise

Module aperture area efficiency (%)

12.5%

13.5%

14.6%

15.6%

TEMPERATURE COEFFICIENTS

Low-Light Performance

Maximum power(Pmax)

-0.43% / ℃

Intensity(W/m2 )

Maximum System Voltage(V)

1000 / 600

Maximum voltage(Vmax)

-0.38% / ℃

1000

Maximum Series Fuse Rating(A)

10

Open circuit voltage(Voc)

-0.33% / ℃

500

Short circuit current(Isc)

-0.03% / ℃

200

TEMPERATURE COEFFICIENTS

Note: Relative to Standard Test Conditions

Note: Relative to Standard Test Conditions (STC): Solar irradiance intensity of 1000 W/m2; AM1.5

(STC): Cell Temperature at 25°C; AM1.5

Temperature Coefficient of Pmpp ( / ℃ )

-0.45

solar reference spectrum (ASTM E892)

solar reference spectrum (ASTM E892)

Temperature Coefficient of Voc ( / ℃ )

-0.36

MECHANICAL SPECIFICATIONS

Length

2017mm

Temperature Coefficient of Isc ( / ℃ )

-0.003

Width

494mm

MECHANICAL SPECIFICATION

Thickness

3mm

Weight(without adhesive)

2.6kg(2.6kg/m2)±5%

Length(mm)

1710

Weight(with adhesive)

3.3kg(3.3kg/m2)±5%

Width(mm)

370

Junction Box - Top Mounted

Micro Junction Box

Cables

4 mm2 dual rated with SOLARLOKTM connectors

Thickness(mm,Maximum at J-Box)

17

Junction Box - Bottom

MC-JM/FM (MC4 Connectors)

Mounted

Weight (Module without adhesive)(kg)

1.7

Front Sheet

Non-stick ETFE(F-40)

Weight / Area(kg/m2)(Module without

2.69

Solar Cells

36 CIGS cells (210 x 100 mm)

adhesive)

Adhesive

ADCO HelioBondTM PVA 600BT butyl mastic

Junction Box Type

IP68

Hot Spot Protection

Bypass diodes at each cell; 1 at junction box

Cable Connections

MC4 Compatible

Materials

Lead free and exempt from RoHS requirements

Maximum Series Fuse Rating

10 Amp

Cell Type

CIGS

Color Options

Black (B) or White (W) backsheet behind cells

QUALIFICATIONS AND CERTIFICATES

OPERATING CONDITIONS

5 year workmanship; 5/10/25 year power output

Temperature Range

-40° C to + 85° C

Maximum System Voltage

1000VDC IEC, 600VDC UL

UL1703,IEC61646,IEC61730(Application Class A)

QUALIFICATIONS AND CERTIFICATES

EN61646,EN61730,UL1703

Materials and workmanship - 5 years;Power output - 25 years (90% @ 10 yrs; 80% @ 25 yrs) Limited Warranty

8

9

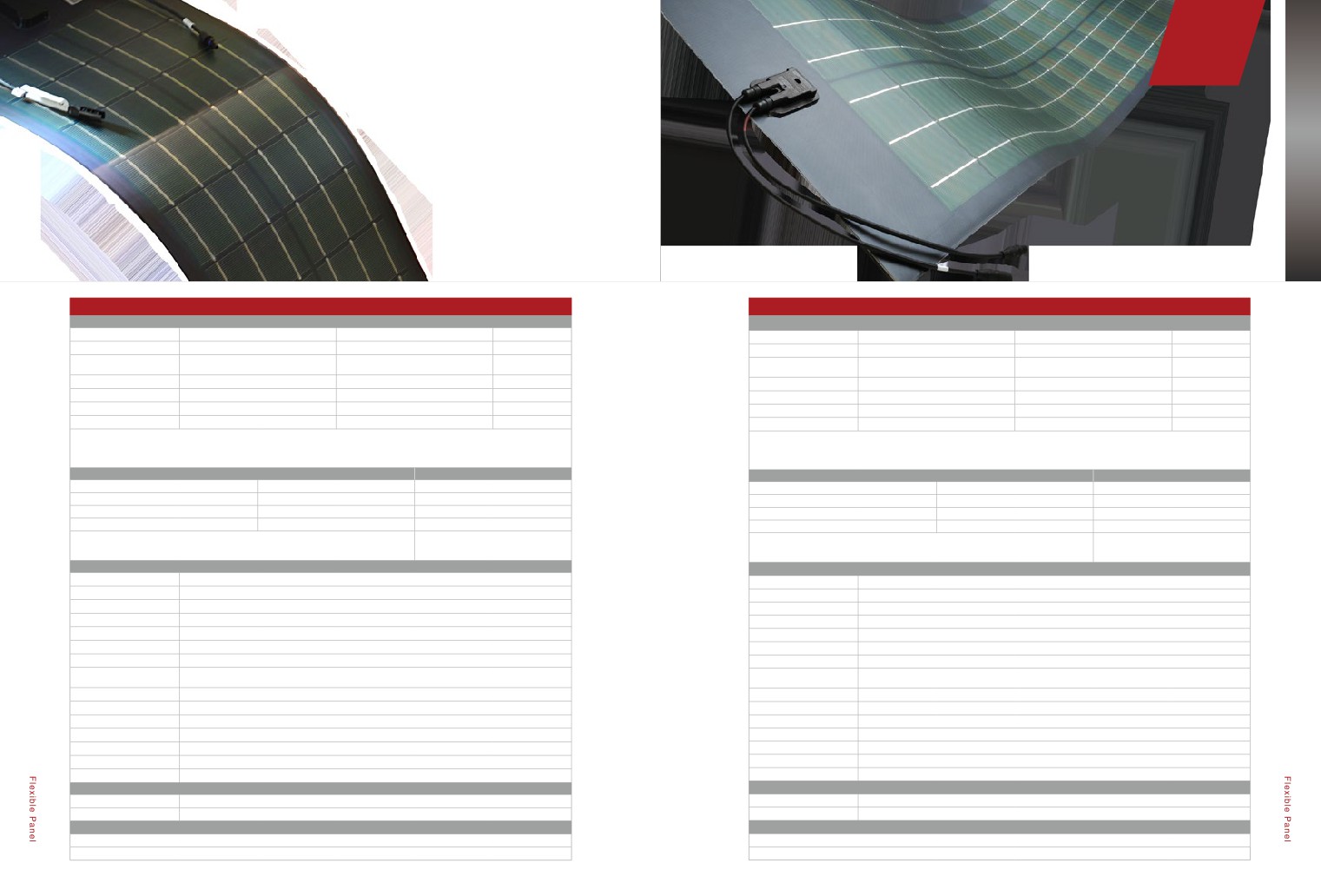

Chapter 01

PRODUCT

PRESENTATION

Global Solar PowerFLEX™ (185/200W)

Global Solar PowerFLEX™(275/300W)

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Capacity rating

Pmax

200W

185W

Capacity rating

Pmax

300W

275W

Tolerance of Pmax

%

+/-5%

+/-5%

Tolerance of Pmax

%

+/-5%

+/-5%

Module aperture area

Module aperture area

%

12.6%

11.7%

%

12.6%

11.5%

efficiency

efficiency

Rated voltage

Vmpp

36.2V

34.7V

Rated voltage

Vmpp

54.3V

51.5V

Rated current

Impp

5.5A

5.3A

Rated current

Impp

5.5A

5.3A

Open circuit voltage

Voc

46.4V

45.6V

Open circuit voltage

Voc

69.7V

67.6V

Short circuit current

Isc

6.4A

6.3A

Short circuit current

Isc

6.4A

6.3A

Note 1: Standard Test Conditions (STC): Cell Temperature at 25° C; Solar irradiance intensity of 1000 W/m2; AM1.5 solar reference spectrum

Note 1: Standard Test Conditions (STC): Cell Temperature at 25° C; Solar irradiance intensity of 1000 W/m2; AM1.5 solar reference spectrum

(ASTM E892)

(ASTM E892)

Note 2: Average efficiency is calculated using the 1.59 m2 aperture area of the module

Note 2: Average efficiency is calculated using the 2.38 m2 aperture area of the module

Note 3: Electrical parameters are +/-10% unless stated otherwise

Note 3: Electrical parameters are +/-10% unless stated otherwise

TEMPERATURE COEFFICIENTS

Low-Light Performance

TEMPERATURE COEFFICIENTS

Low-Light Performance

Maximum power(Pmax)

-0.43% / ℃

Intensity(W/m2 )

Maximum power(Pmax)

-0.43% / ℃

Intensity(W/m2 )

Maximum voltage(Vmax)

-0.38% / ℃

1000

Maximum voltage(Vmax)

-0.38% / ℃

1000

Open circuit voltage(Voc)

-0.33% / ℃

500

Open circuit voltage(Voc)

-0.33% / ℃

500

Short circuit current(Isc)

-0.03% / ℃

200

Short circuit current(Isc)

-0.03% / ℃

200

Note: Relative to Standard Test Conditions

Note: Relative to Standard Test Conditions

Note: Relative to Standard Test Conditions (STC): Solar irradiance intensity of 1000 W/m2; AM1.5

Note: Relative to Standard Test Conditions (STC): Solar irradiance intensity of 1000 W/m2; AM1.5

(STC): Cell Temperature at 25°C; AM1.5

(STC): Cell Temperature at 25°C; AM1.5

solar reference spectrum (ASTM E892)

solar reference spectrum (ASTM E892)

solar reference spectrum (ASTM E892)

solar reference spectrum (ASTM E892)

MECHANICAL SPECIFICATIONS

MECHANICAL SPECIFICATIONS

Length

3881mm

Length

5745mm

Width

494mm

Width

494mm

Thickness

3mm

Thickness

3mm

Weight(without adhesive)

4.9kg(2.6kg/m2)±5%

Weight(without adhesive)

7.2kg(2.6kg/m2)±5%

Weight(with adhesive)

6.3kg(3.3kg/m2)±5%

Weight(with adhesive)

9.3kg(3.3kg/m2)±5%

Junction Box - Top Mounted

Micro Junction Box

Junction Box - Top Mounted

Micro Junction Box

Cables

4 mm2

dual rated with SOLARLOKTM connectors

Cables

4 mm2 dual rated with SOLARLOKTM connectors

Junction Box - Bottom

Junction Box - Bottom

MC-JM/FM (MC4 Connectors)

MC-JM/FM (MC4 Connectors)

Mounted

Mounted

Front Sheet

Non-stick ETFE(F-40)

Front Sheet

Non-stick ETFE(F-40)

Solar Cells

72 CIGS cells (210 x 100 mm)

Solar Cells

108 CIGS cells (210 x 100 mm)

Adhesive

ADCO HelioBondTM PVA 600BT butyl mastic

Adhesive

ADCO HelioBondTM PVA 600BT butyl mastic

Hot Spot Protection

Bypass diodes at each cell; 1 at junction box

Hot Spot Protection

Bypass diodes at each cell; 1 at junction box

Materials

Lead free and exempt from RoHS requirements

Materials

Lead free and exempt from RoHS requirements

Maximum Series Fuse Rating

10 Amp

Maximum Series Fuse Rating

10 Amp

Color Options

Black (B) or White (W) backsheet behind cells

Color Options

Black (B) or White (W) backsheet behind cells

OPERATING CONDITIONS

OPERATING CONDITIONS

Temperature Range

-40° C to + 85° C

Temperature Range

-40° C to + 85° C

Maximum System Voltage

1000VDC IEC, 600VDC UL

Maximum System Voltage

1000VDC IEC, 600VDC UL

QUALIFICATIONS AND CERTIFICATES

QUALIFICATIONS AND CERTIFICATES

EN61646,EN61730,UL1703

EN61646,EN61730,UL1703

Materials and workmanship - 5 years;Power output - 25 years (90% @ 10 yrs; 80% @ 25 yrs) Limited Warranty

Materials and workmanship - 5 years;Power output - 25 years (90% @ 10 yrs; 80% @ 25 yrs) Limited Warranty

10

11

Chapter 01

PRODUCT

PRESENTATION

Key product features:

PET sheet substrate, light weight per unit area;

Good low-light effect, low temperature coefficient,

various colors.

1.2.3

Light weight Panel

HNS-BT65QA

HNS-BT65QB

CHARACTERISTIC

CHARACTERISTIC

Panel Type

PIN/PIN/PIN Triple-junction a-Si/Ge Cell

Panel Type

PIN/PIN/PIN Triple-junction a-Si/Ge Cell

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Maximum power(V)

70

Maximum power(V)

70

Maximum voltage(A)

0.93

Maximum voltage(A)

0.93

Output Circuit Voltage (V)

89

Output Circuit Voltage (V)

89

Short Circuit Current (A)

1.12

Short Circuit Current (A)

1.12

Power Output Tolerance(W)

0/+3

Power Output Tolerance(W)

0/+3

Maximum System voltage(V)

1000

Maximum System voltage(V)

1000

Maximum Series Fuse Rating(A)

2

Maximum Series Fuse Rating(A)

2

TEMPERATURE COEFFICIENTS

TEMPERATURE COEFFICIENTS

Temperature Coefficient of Isc ( / ℃ )

0.02%

Temperature Coefficient of Isc ( / ℃ )

0.02%

Temperature Coefficient of Voc ( / ℃ )

-0.20%

Temperature Coefficient of Voc ( / ℃ )

-0.20%

Temperature Coefficient of Pmpp ( / ℃ )

-0.19%

Temperature Coefficient of Pmpp ( / ℃ )

-0.19%

MECHANICAL SPECIFICATION

MECHANICAL SPECIFICATION

Length(mm)

1245

Length(mm)

1245

Width(mm)

635

Width(mm)

635

Height(mm,Junction Box not included)

4.0

Height(mm,Junction Box not included)

4.8

Weight (kg)

8.9

Weight (kg)

9.0

Area(m2)

0.79

Area(m2)

0.79

Junction box Type

Back connecting boxes

Junction box Type

Back connecting boxes

Thickness of Junction Box(mm)

20

Thickness of Junction Box(mm)

20

Junction Box Class

IP67

Junction Box Class

IP67

Cable Length(mm)

450

Cable Length(mm)

450

Materials

EVA

Materials

EVA

Front cover

3.2mm TCO

Front cover

2.5mm TCO

Back cover

0.37mm PET

Back cover

2.0 Tempered glass

12

13

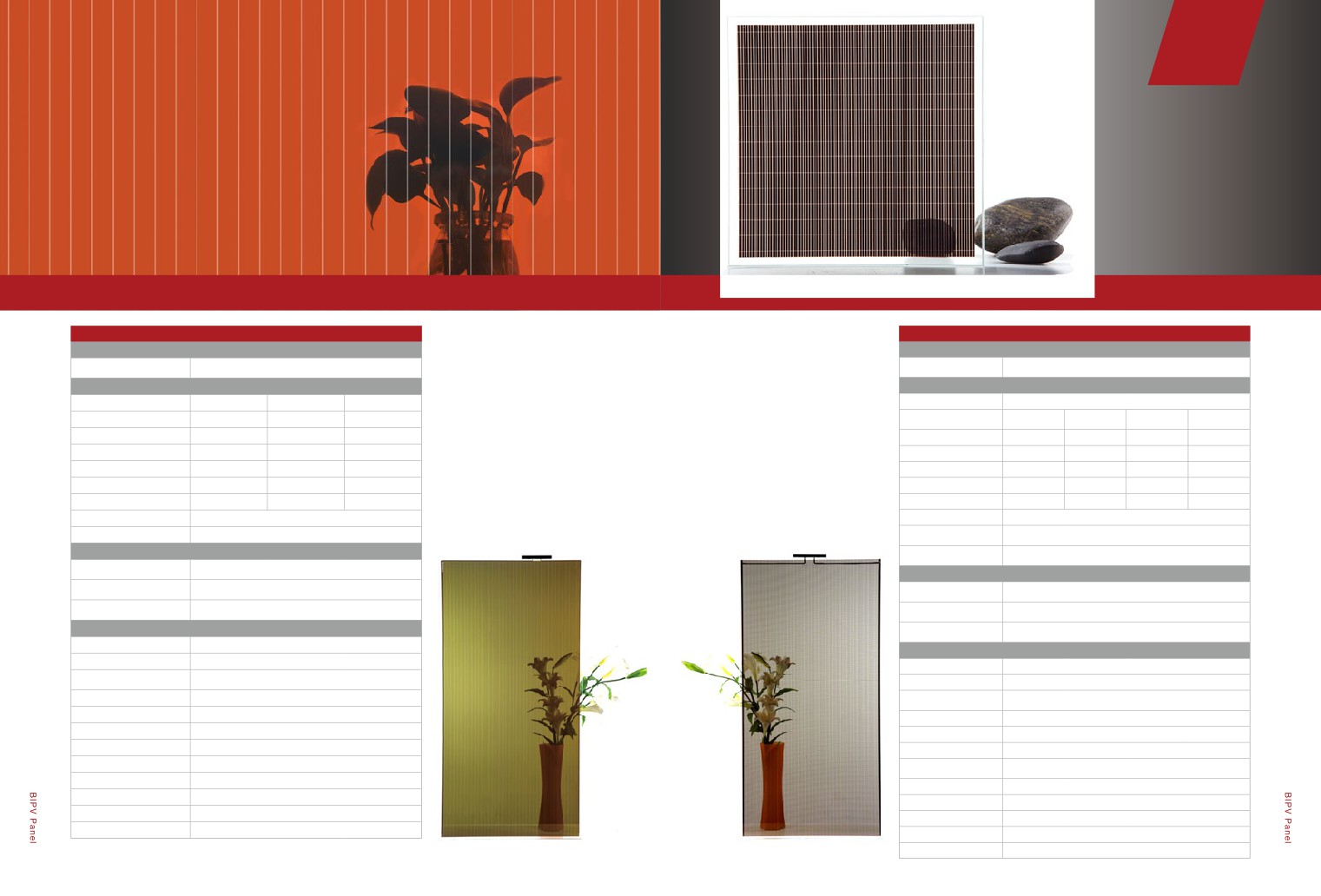

Chapter 01

PRODUCT

1.3

BIPV Panel

PRESENTATION

Key product features:

Key product features:

Translucent uniform penetration of different

5% to 30% transmittance options, various

spectral selectivity, good low-light effect, can

scribing linewidth options, can be widely

be widely used in agriculture greenhouse.

applied to walls, skylights, etc.

1.3.1

Back electrode translucent Panel

HNS-BS30/BD40/BT55TB

HNS-BT51TK

CHARACTERISTIC

CHARACTERISTIC

PIN a-Si/Ge Cell, Glass-glass/Side J-box /see-through

PIN/PIN/PIN Triple-junction a-Si/Ge Cell,Glass-glass/Side J-box /

Panel Type

Panel Type

module

see-through module

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Transmittance

40%

20%

10%

Transmittance

20%

Laser etching liner width

Maximum Power(W)

30

40

55

0.3

0.67

1

3

(mm)

Maximum Power Voltage (V)

20

46

67

Maximum Power(W)

45

51

51

51

Maximum Power Current (A)

1.5

0.87

0.82

Maximum Power Voltage (V)

64

69

69

69

Output Circuit Voltage (V)

31

58

84

Maximum Power Current (A)

0.71

0.74

0.74

0.74

Short Circuit Current (A)

2

1.08

0.99

Output Circuit Voltage (V)

84

89

89

89

Power Output Tolerance(W)

±1

±1.5

±2

Short Circuit Current (A)

0.89

0.89

0.89

0.89

Maximum System voltage(V)

1000

Power Output Tolerance(W)

0 / +2

Maximum System voltage

Maximum Series Fuse Rating(A)

3

1000

(V)

TEMPERATURE COEFFICIENTS

Maximum Series Fuse Rating

2

(A)

Temperature Coefficient of Isc ( /

0.02%

℃)

TEMPERATURE COEFFICIENTS

Temperature Coefficient of Voc (

Temperature Coefficient of

-0.20%

0.02%

/ ℃ )

Isc ( / ℃ )

Temperature Coefficient of Pmpp

Temperature Coefficient of

-0.19%

-0.20%

( / ℃ )

Voc ( / ℃ )

MECHANICAL SPECIFICATION

Temperature Coefficient of

-0.19%

Pmpp ( / ℃ )

Length(mm)

1245

MECHANICAL SPECIFICATION

Width(mm)

635

Length(mm)

1245

Height(mm,Junction Box not

9.7

Width(mm)

635

included)

Weight (kg)

18.6

Height(mm,Junction Box

9.7

not included)

Area(m2)

0.79

Weight (kg)

18.6

Junction box Type

Side Junction box

Area(m2)

0.79

Thickness of Junction Bo(mm)

12.6

Junction box Type

Side Junction box

Junction Box Class

IP67

Thickness of Junction Box

12.6

(mm)

Cable Length(mm)

450

Junction Box Class

IP67

Materials

PVB

Cable Length(mm)

450

Front cover

3.2mm TCO

Materials

PVB

Back cover

6.0mm Semi-tempered/ Tempered glass

Front cover

3.2mm TCO

Back cover

6.0mm Semi-tempered/ Tempered glass

14

15

Chapter 01

PRODUCT

PRESENTATION

Key product features:

Key product features:

Various colors, applicable to all types of

Hollow panel, meeting the energy

architectural curtain walls that have color

efficiency requirement of buildings.

requirements.

1.3.3

Colored translucent Panel

1.3.4

Hollow Panel

HNS-BT50C

HNS-BT45Z

CHARACTERISTIC

CHARACTERISTIC

Substrate

TCO Glass

Substrate

TCO Glass

PIN/PIN/PIN Triple-junction a-Si/Ge Cell,Glass-glass/Side J-box /

Triple-junction a-Si/Ge Cell,Glass-glass/Side J-box /see-through /

Panel Type

Panel Type

Colorful/ see-through module

Insulating module

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Color

Blue / Green / Yellow / Orange

Transmittance

20%

Transmittance

20%

Maximum Power(W)

45

Silicone

Maximum Power(W)

51

Maximum Power Voltage (V)

64

Maximum Power Voltage (V)

69

Maximum Power Current (A)

0.71

Maximum Power Current (A)

0.74

Output Circuit Voltage (V)

84

Output Circuit Voltage (V)

88

Short Circuit Current (A)

0.89

Short Circuit Current (A)

0.89

Power Output Tolerance(W)

0/+2

Power Output Tolerance(W)

0/+2

Maximum System voltage

1000

(V)

Maximum System voltage

1000

Maximum Series Fuse Rating

(V)

2

(A)

Maximum Series Fuse Rating

2

(A)

TEMPERATURE COEFFICIENTS

TEMPERATURE COEFFICIENTS

Front 3.2mm TCO glass

Temperature Coefficient of

0.02%

Isc ( / ℃ )

Temperature Coefficient of

Back Tempered glass

0.02%

Temperature Coefficient of

Isc ( / ℃ )

-0.20%

Desiccant

Voc ( / ℃ )

Temperature Coefficient of

-0.20%

Tempered glass

Temperature Coefficient of

Voc ( / ℃ )

-0.19%

Pmpp ( / ℃ )

Temperature Coefficient of

-0.19%

Pmpp ( / ℃ )

MECHANICAL SPECIFICATION

MECHANICAL SPECIFICATION

Length(mm)

Customized

Length(mm)

1245

Width(mm)

Width(mm)

635

Height(mm,Junction Box

27.7

not included)

Height(mm,Junction Box

9.7

Weight (kg)

30.4

not included)

Weight (kg)

18.6

Area(m2)

0.79

Area(m2)

0.79

Junction box Type

Side Junction box

Junction box Type

Side Junction box

Thickness of Junction Box

12.6

(mm)

Thickness of Junction Box

12.6

Junction Box Class

IP67

(mm)

Junction Box Class

IP67

Cable Length(mm)

450

Cable Length(mm)

450

Materials

PVB

Materials

PVB

Front cover

3.2mm TCO

Front cover

3.2mm TCO

Back cover

6.0mm Semi-tempered/ Tempered glass

16

Back cover

6.0mm Semi-tempered/ Tempered glass

Insulating glass

6.0mm Tempered glass

17

Chapter 01

PRODUCT

PRESENTATION

Key product features:

Key product features:

Double-sided power, high overall power

Diverse modeling, can be tailor-made

generation efficiency, can be widely used

to fit the architectural design of the

for sound barrier or noise screens.

building.

1.3.5

Double-sided power Panel

1.3.6

Allotype Panel

HNS-BT123S

CHARACTERISTIC

Substrate

TCO Glass

HNS-BT15Y

PIN/PIN/PIN Triple-junction a-Si/Ge Cell,PIN/PIN a-Si/Ge tandem

CHARACTERISTIC

Panel Type

Cell,Triple Glazing/ Double Side Junction Box

Substrate

TCO Glass

ELECTRICAL PERFORMANCE

PIN/PIN/PIN Triple-junction a-Si/Ge Cell,Glass-glass/Side J-box /

Panel Type

Maximum Power(W)

65

58

see-through module

Maximum Power Voltage (V)

70

43

ELECTRICAL PERFORMANCE

Maximum Power Current (A)

0.93

1.36

Transmittance

20%

Output Circuit Voltage (V)

89

58.5

Maximum Power(W)

15

Short Circuit Current (A)

1.12

1.56

Maximum Power Voltage (V)

60

Power Output Tolerance(W)

0/+3

±1

Maximum Power Current (A)

0.25

Maximum System voltage

Output Circuit Voltage (V)

80

1000

(V)

Maximum Series Fuse Rating

Short Circuit Current (A)

0.3

5

(A)

Power Output Tolerance(W)

0/+1

TEMPERATURE COEFFICIENTS

Maximum System voltage

Temperature Coefficient of

1000

0.02%

(V)

Isc ( / ℃ )

Maximum Series Fuse Rating

Temperature Coefficient of

2

-0.20%

(A)

Voc ( / ℃ )

TEMPERATURE COEFFICIENTS

Temperature Coefficient of

-0.19%

Pmpp ( / ℃ )

Temperature Coefficient of

0.02%

Isc ( / ℃ )

MECHANICAL SPECIFICATION

Temperature Coefficient of

-0.20%

Length(mm)

1245

Voc ( / ℃ )

Temperature Coefficient of

Width(mm)

635

-0.19%

Pmpp ( / ℃ )

Height(mm,Junction Box

8

MECHANICAL SPECIFICATION

not included)

Weight (kg)

15.8

Length(mm)

Area(m2)

0.79

Weight (kg)

Customized

Junction Box Type

Side Junction box

Area(m2)

Thickness of Junction Box

12.6

Height(mm,Junction Box

(mm)

7.5

not included)

Junction Box Class

IP67

Junction box Type

Side Junction box

Cable Length(mm)

450

Thickness of Junction Box

12.6

Materials

EVA

(mm)

Front cover

2.5mm TCO

Junction Box Class

IP67

Intermediate glass

2.0mm Non-Tempered glass

Cable Length(mm)

450

Back cover

2.5mm TCO

Materials

PVB

18

Front cover

3.2mm TCO

19

Back cover

4.0mm Semi-tempered/ Tempered glass

Chapter 01

PRODUCT

PRESENTATION

Key product features:

Key product features:

Three layers of plastic sheets with multiple

Integration of corporate logo with solar

cell chips pulled and spliced, can meet the

panels to achieve a win-win solution for

requirement of large size curtain walls.

power generation and corporate branding.

1.3.7

Splice Panel

1.3.8

LOGO Panel

HNS-BT153TP

HNL-1

CHARACTERISTIC

CHARACTERISTIC

Substrate

TCO Glass

Substrate

TCO Glass

Panel Type

PIN/PIN/PIN Triple-junction a-Si/Ge Cell

Panel Type

PIN/PIN/PIN Triple-junction a-Si/Ge Cell

ELECTRICAL PERFORMANCE

ELECTRICAL PERFORMANCE

Transmittance

20%

Transmittance

40%

Maximum Power(W)

153

Maximum Power(W)

32

Maximum Power Voltage (V)

62

Maximum Power Voltage (V)

63

Maximum Power Current (A)

2.48

Maximum Power Current (A)

0.51

Output Circuit Voltage (V)

82

Output Circuit Voltage (V)

84

Short Circuit Current (A)

3.28

Short Circuit Current (A)

0.67

Power Output Tolerance(W)

0/+5

Power Output Tolerance(W)

0/+3

Maximum System voltage(V)

1000

Maximum System voltage(V)

1000

Maximum Series Fuse Rating(A)

5

Maximum Series Fuse Rating(A)

2

TEMPERATURE COEFFICIENTS

TEMPERATURE COEFFICIENTS

Temperature Coefficient of Isc ( / ℃ )

0.02%

Temperature Coefficient of Isc ( / ℃ )

0.02%

Temperature Coefficient of Voc ( / ℃ )

-0.20%

Temperature Coefficient of Voc ( / ℃ )

-0.20%

Temperature Coefficient of Pmpp ( /

-0.19%

Temperature Coefficient of Pmpp ( / ℃ )

-0.19%

℃)

MECHANICAL SPECIFICATION

MECHANICAL SPECIFICATION

Length(mm)

2540

Length(mm)

1245

Width(mm)

1245

Width(mm)

635

Height(mm,Junction Box not

Height(mm,Junction Box not

16.2

9.7

included)

included)

Weight (kg)

124

Weight (kg)

18.6

Area(m2)

3.16

Area(m2)

0.79

Junction Box Type

Side Junction box

Junction box Type

Back connecting boxes

Thickness of Junction Box(mm)

12.6

Thickness of Junction Box(mm)

20

Junction Box Class

IP67

Junction Box Class

IP67

Cable Length(mm)

1800

Cable Length(mm)

450

Materials

PVB

Materials

EVA/PVB

Front cover

6.0mm Semi-tempered/ Tempered glass

Front cover

3.2mm TCO

Intermediate glass

3.2mm TCO

Back cover

4.0mm Non-Tempered glass

Back cover

6.0mm Semi-tempered/ Tempered glass

20

21

SOLUTIONS

2.1 Utility Scale

2.4

Flex Rooftop

2.7

Comsummer

2.1.1 Utility Scale

2.4.1 Advantages

2.7.1

RDS

2.1.2 Wind and PV solar power hybrid

2.4.2 Installation Method

2.7.2

Solar Camping Kit

system

2.7.3

Solar Smart Table

2.1.3 Farming and PV solar

2.7.4

Flexible Solar Charging

2.1.4 Hydropower and PV solar hybrid

Bag

2.5

Vehicle and Yacht application

system

2.5.1 Solar sunroof solution

2.1.5 Fishing and PV solar

2.5.2 Yacht/ ship application

2.1.6 Solar pumping system

2.5.3 Power solutions for mobile

2.1.7 Landfill thin-film solar plant

applications

2.2 Distributed generation

2.2.1

Forms of application

2.6

Household Solar PV system

2.6.1

General View

2.6.2

Hanergy Household Solar

2.3

BIPV

PV system

2.3.1 BIPV System Solutions

2.6.3

Earning and Saving

2.3.2 BIPV Applications

2.6.4

One-Stop Service

2.3.3 Hanergy Headquarters BIPV

2.6.5

Hanergy Stores around the

Project

World

Chapter

02

SOLUTIONS

2.1

Utility Scale

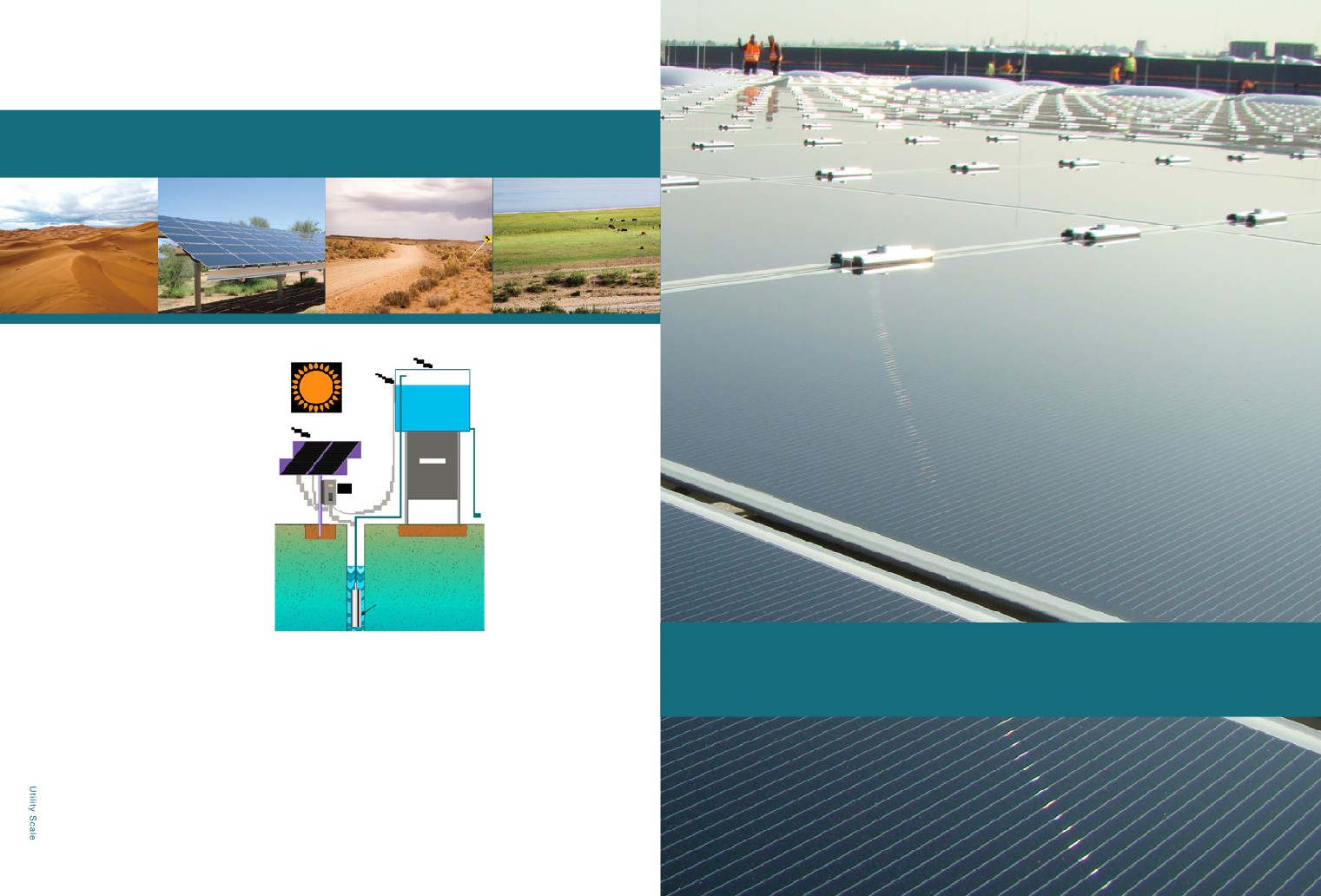

2.1.1

Utility Scale

Large utility scale is suitable for installation in waste hills or wastelands, deserts, mudflat areas,

etc., to make full use of the idle land resources.

2 4

3 5

2.1.2 Wind and PV solar power

2.1.4 Hydropower and PV solar

hybrid system

hybrid system

The complementary programs of wind and solar

The effective combination of hydroelectric power

power hybrid system in large utility scales enable the

generation with film power generation, enables

rational utilization of the wind and solar resources. By

hydropower and solar energy to display their

building both solar utility scale and wind power plants

complementary strengths, and to form a mutually

in a given region, they can share the transformer and

complementing power generation model. Using clean

the transmission lines in the region to improve grid

and renewable energy to improve the operational

efficiency and achieve a relatively stable power output.

efficiency of hydroelectric power stations, provide

more access and more effective options for water

conservancy and hydropower enterprises’ innovation

and development efforts.

2.1.3 Farming and PV solar

2.1.5 Fishing and PV solar

After the completion of the ground station, the PV array

Installing the solar power system over the ponds is

blocks the sun's radiation on the ground and effectively

an effective way to use the land resources of the fish

reduces water evaporation, and making the soil

pond. The panels block the sunshine and create a

conditions suitable for ground vegetation to recover. This

shade. This not only enables the fish pond owner to

improves the land use efficiency of the power plant and

get an additional income from power generation, but

25

increases the project output.

also benefits the growth of fish in the pond.

2.1.6 Solar pumping system

Solar pumping system is consisted of panels, controller (invertor), high-performance pumps and pipes, valves, etc.

Water tower

Scope of application:

Water

level

monitor

• Irrigation

• Desert control

An array of thin-film

• Grassland animal husbandry

battery modules

• Urban water views

• Domestic water

Controller

• Sewage treatment

• Sea water desalination

Pump

Solar pumping system illustration chart

2.1.7 landfill thin-film solar plant

2.2

Distributed generation

The effective application of PV solar technology on premises of waste landfills

encounters many difficulties. When the plant is just completed, there could be large

amount of sinking, with uneven local settlements. Hence it is difficult to determine the

bearing capacity of the foundation. The uncertainty of landfill materials and surface

subsidence carries great impact, while at the same time, exudate and methane

fermentation also contribute to the non-utilization of this land resources. As the

degradation and stabilization of landfills require more than 20 years, the construction

of landfill power plants may adopt an inexpensive technical solution, to avoid adverse

factors affecting electricity generation and security of thin-film arrays. Make full use of

26

the land value during the degradation stabilizing period.

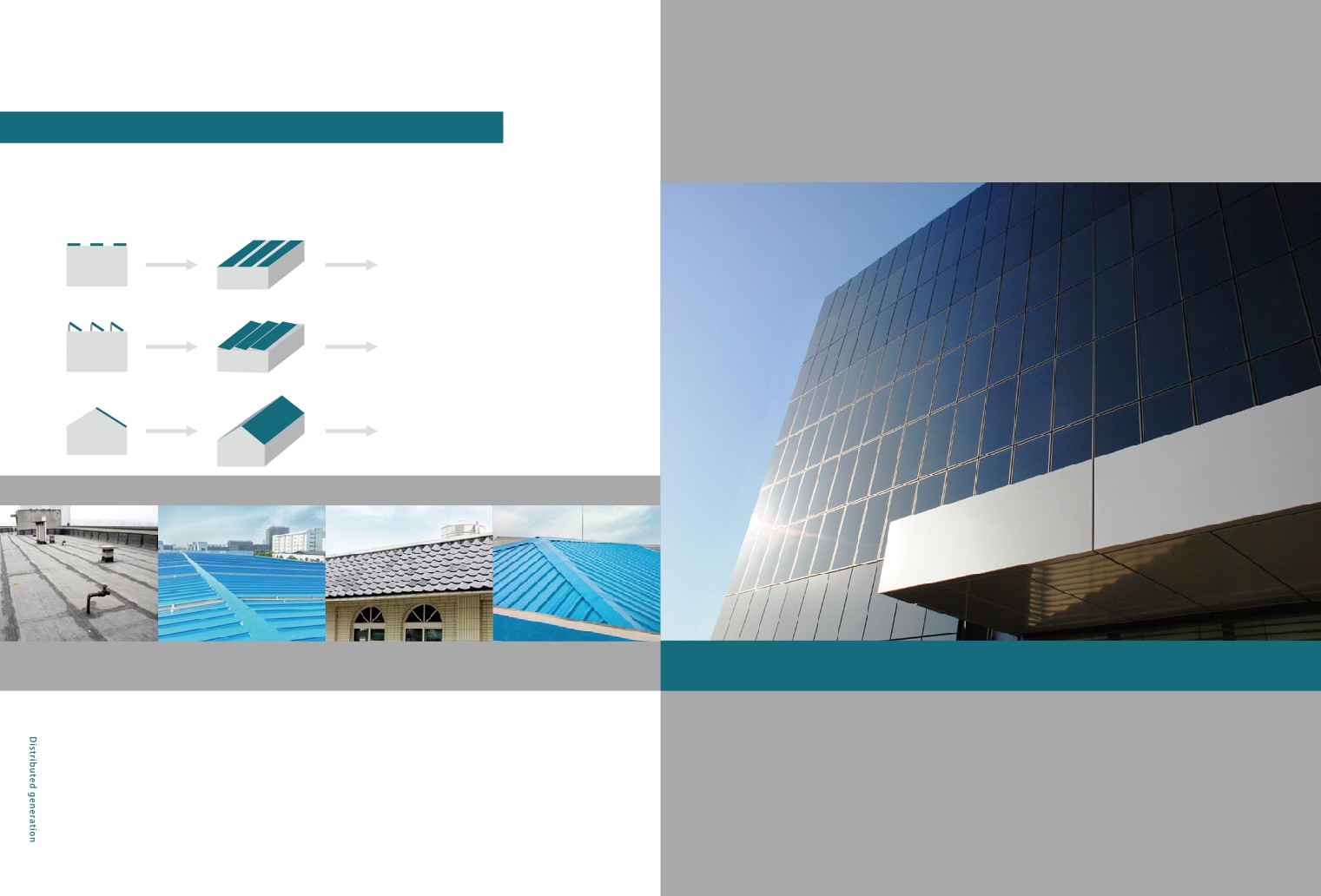

2.2.2

Forms of application

Distributed generation mainly include thin film solar panels, DC distribution equipments, inversion

equipments, low-voltage distribution equipments, pressure-rise equipments, environment

monitoring equipments and monitoring system. According to the forms of roof, the installation can

be mainly classified into two types: flat roof and sloping roof.

horizontal installation, maximum

installed capacity

Flat roof

best slanting installation, maximum

generating capacity

Flat roof

dip angle installation, increase

generating capacity

Cement flat roof

Flat roof

Cement flat roof

Cement flat roof

Flat steel tile roof

Tiled sloping roofs

Steel tile sloping roofs

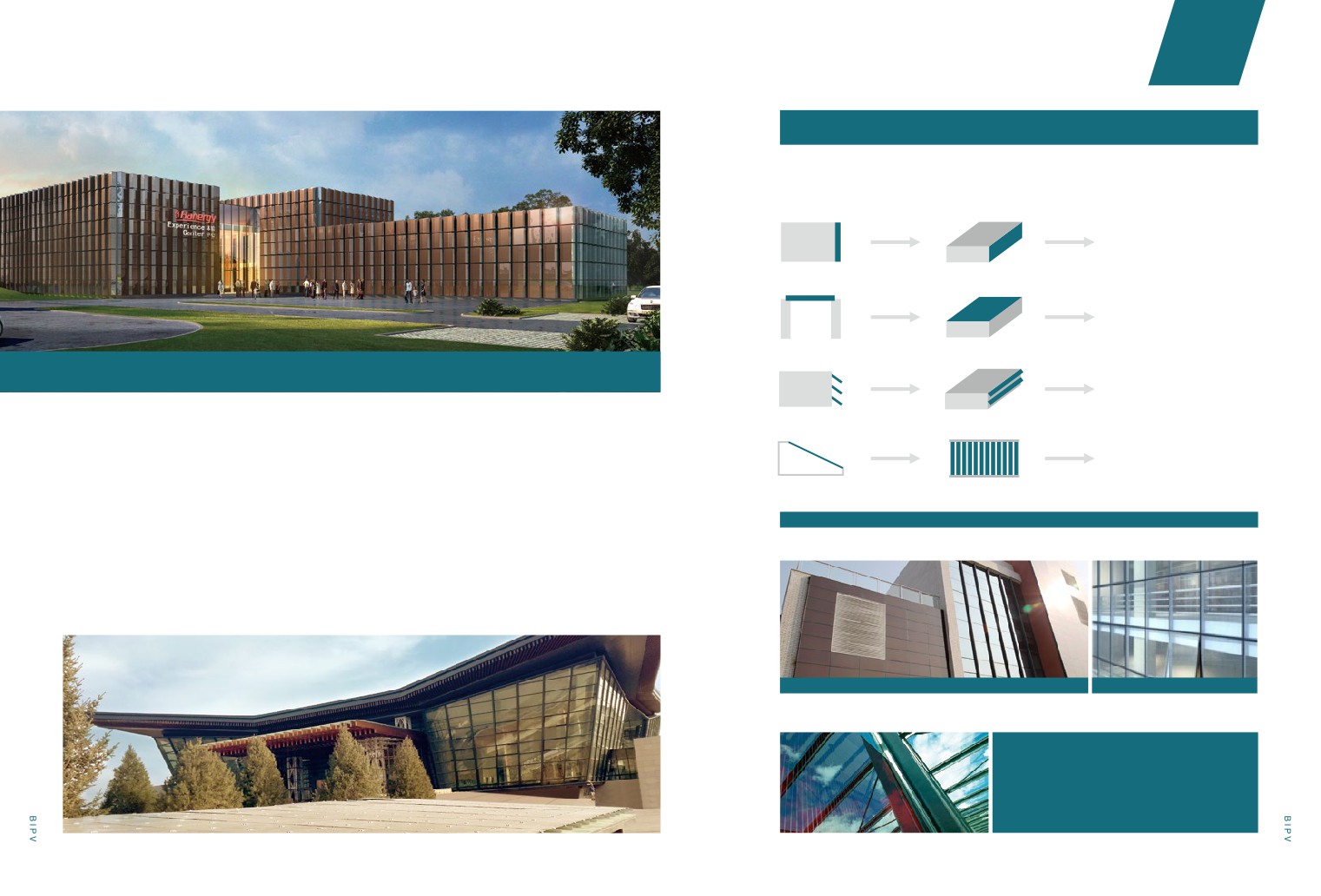

2.3

BIPV

Technical features:

1. The temperature coefficient of thin film panels is smaller than that of crystalline silicon panels. When installed

on the roof, especially in small dip angle installation, heat dissipation of modules is limited, and thin film

modules may have better power output characteristics.

2. Thin film has the advantage of weak light. In the condition of lower solar irradiance, such as in the morning,

evening and rainy days, because of higher optical absorption coefficient of thin film solar cell, the generating

capacity of thin film panels is obviously higher than crystalline silicon panels. Especially when the panels are

28

not installed at the best dip angle, the advantage is more obvious.

Chapter

02

SOLUTIONS

2.3.2

BIPV Applications

According to the different situations, functions and installation methods, BIPV applications could be divided

into solar curtain wall, solar canopy, solar skylight, solar noise barrier, solar agricultural greenhouse and

etc.

Replace hollow glass, thermal

insulation, noise reduction function

Solar Curtain Wall

Meet the demand of architectural

lighting; provide power and energy-

saving

Solar Skylight

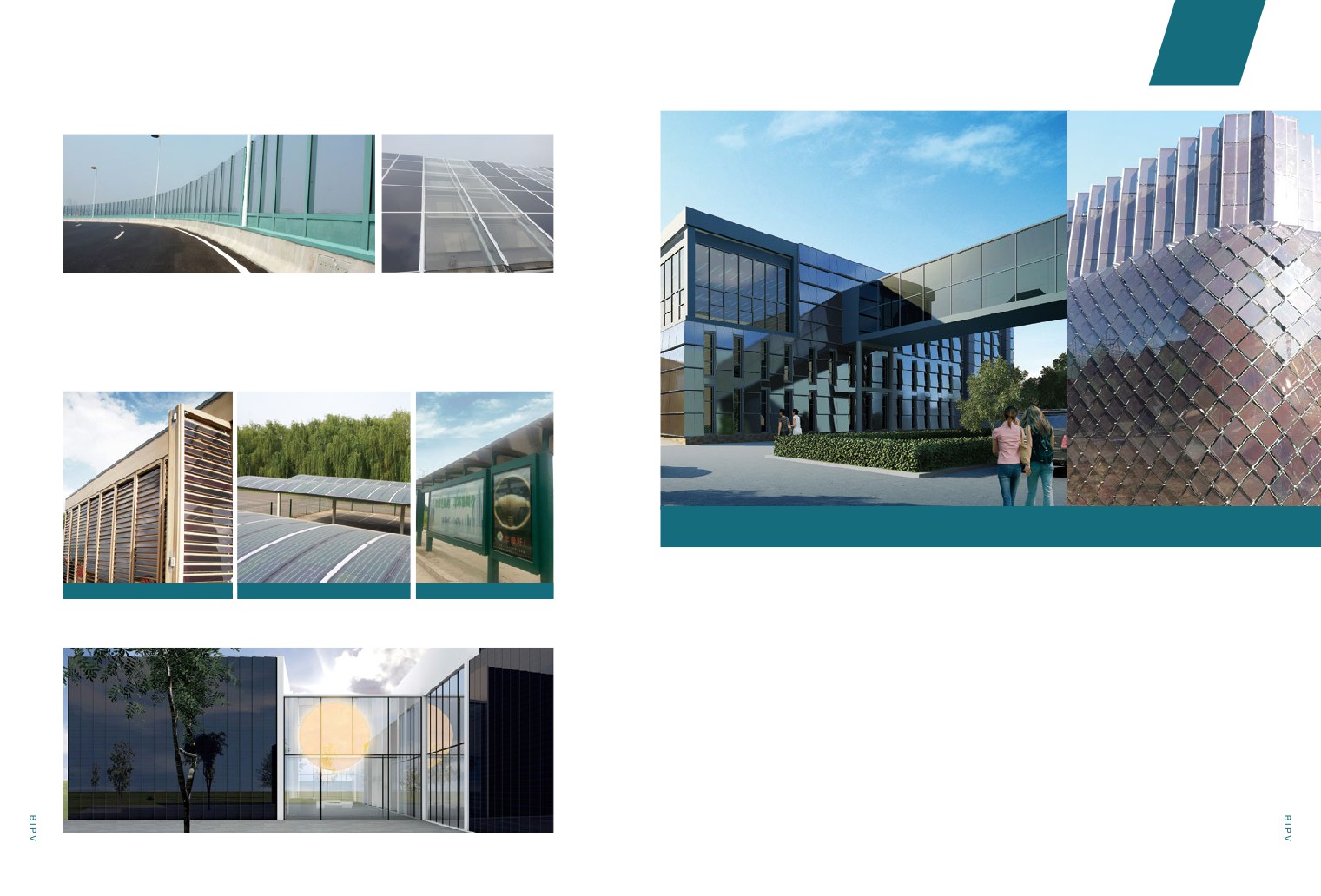

2.3.1

BIPV System Solutions

Provide power and shelter from sun

as building components

Solar Canopy

1. Building Structure Design

• Support structure research for BIPV

Provide power with no additional

• Research and design for advanced BIPV projects

area needed

Solar agricultural greenhouse

2. Electrical Design

• Innovative research for BIPV electrical technology

BIPV Applications

• Supporting electrical design

PV Solar Curtain Wall

3. System Integration Research

• Basic application research of intelligent building

• Integration research for BIPV and building function

Bright Frame PV Solar Curtain Wall

Concealed Frame PV Solar Curtain Wall

Solar Skylight

Technical Characteristics:

With a wide range of panels and installation methods,

the product can provide efficient electricity to the

building while at the same time meeting its functional

requirements such as energy-saving, thermal

insulation, waterproof, noise reduction, etc.

30

31

02

Chapter

SOLUTIONS

Other forms of BIPV application/ highway noise screens

Solar Agricultural Greenhouse

Hanergy Group Headquarters BIPV Renderings

Technical Characteristics:No additional area required, provide power for heat preservation, ventilation,

irrigation systems. It is particularly suitable for areas where power grid is underdeveloped.

Advantages of thin-film panels: Allow red light to pass through and enable crops to grow. Absorb part of

ultraviolet light and reduce UV damage to crops.

Other forms of BIPV application

2.3.3

Hanergy Headquarters BIPV Project

PV Solar Blinds

PV Solar Carport

PV Solar Bus Station

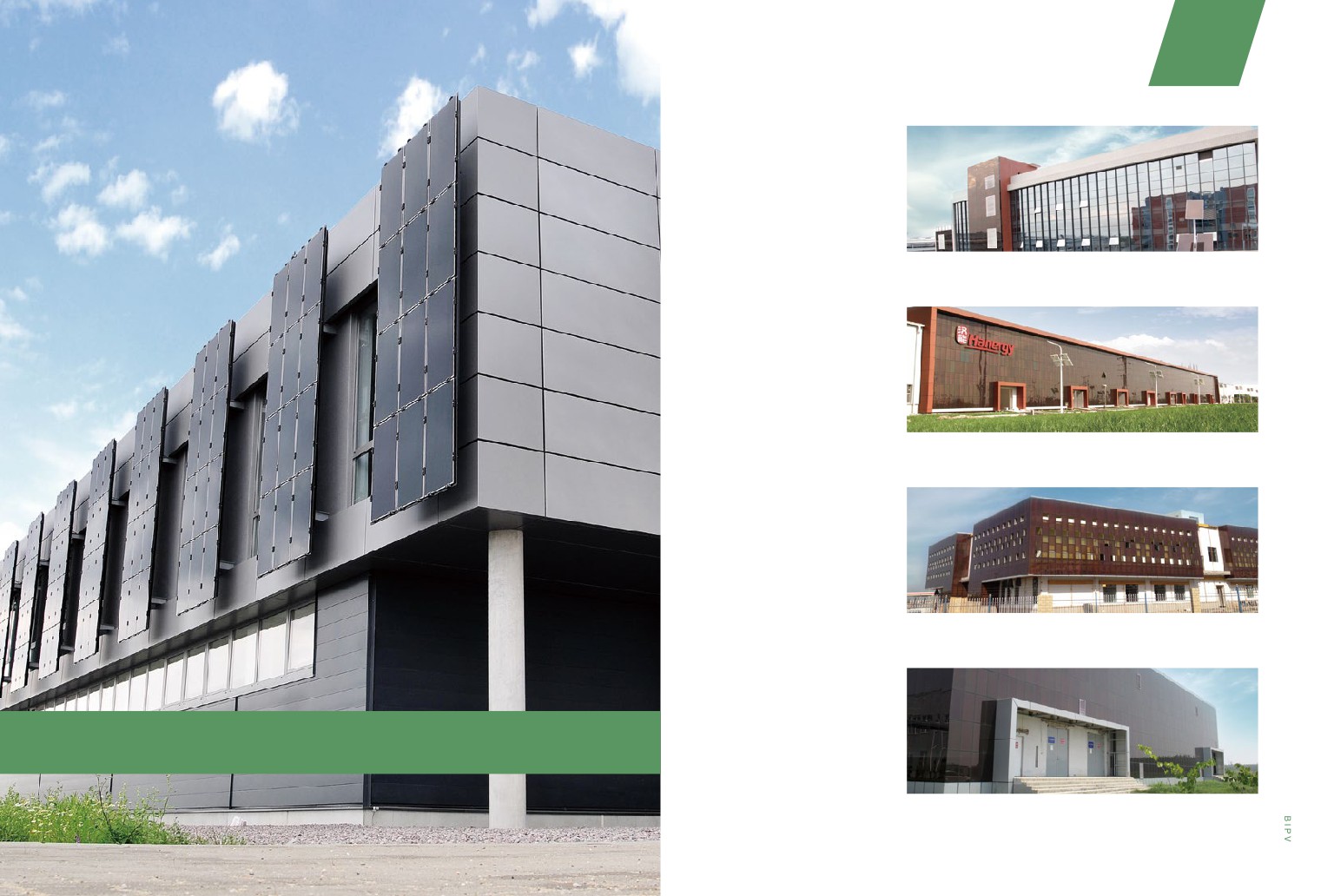

Hanergy Headquarters BIPV Project is located in the Beijing Olympics Forest Park. With installed

capacity of 315kw, the project construction started in March 2014 and completed in October of the

Hanergy Clean Energy Exhibition Center

same year. While maintaining the original layout of the building plane functions, the project makes

good use of different types of PV panels according to the needs of lighting, shading and ventilation.

It is a perfect combination of Hanergy’s PV technology and building.

Floor 1and2 of Tower B adopts the hyperboloid structure, installs custom double-glass panels with

45° diagonal layout, and fitting facade with parametric design.

Floor 3 of Tower B adopts the standard double-glass panels with integral facade appears wavy.

Facade and rooftop of corridor adopts a large size hollow panels with replace of glass curtain wall

elements and with the effect of homogeneous transmittance and a variety of colors.

32

33

Chapter

02

SOLUTIONS

High power generation

2.4

Flex Rooftop

High efficiency CIGS

· Efficiency as high as 16%

High performance

2.4.1

Advantages

· Performs in all light conditions

· Shade tolerant

Designed specifically for rooftops

Light weight

Covers entire roof area

· Less than 4kg/m2

· Lays flat. No tilt required

· Minimum panel spacing required

Integrates with roofing surface

· No mounting hardware

· No roof penetrations

Low installation costs

· Superior wind resistance

· Flexible. Fits many roof types

Direct Adhesion

· Innovative architectural effect

· Eliminating racking reduces BOS cost

34

35

02

Chapter

SOLUTIONS

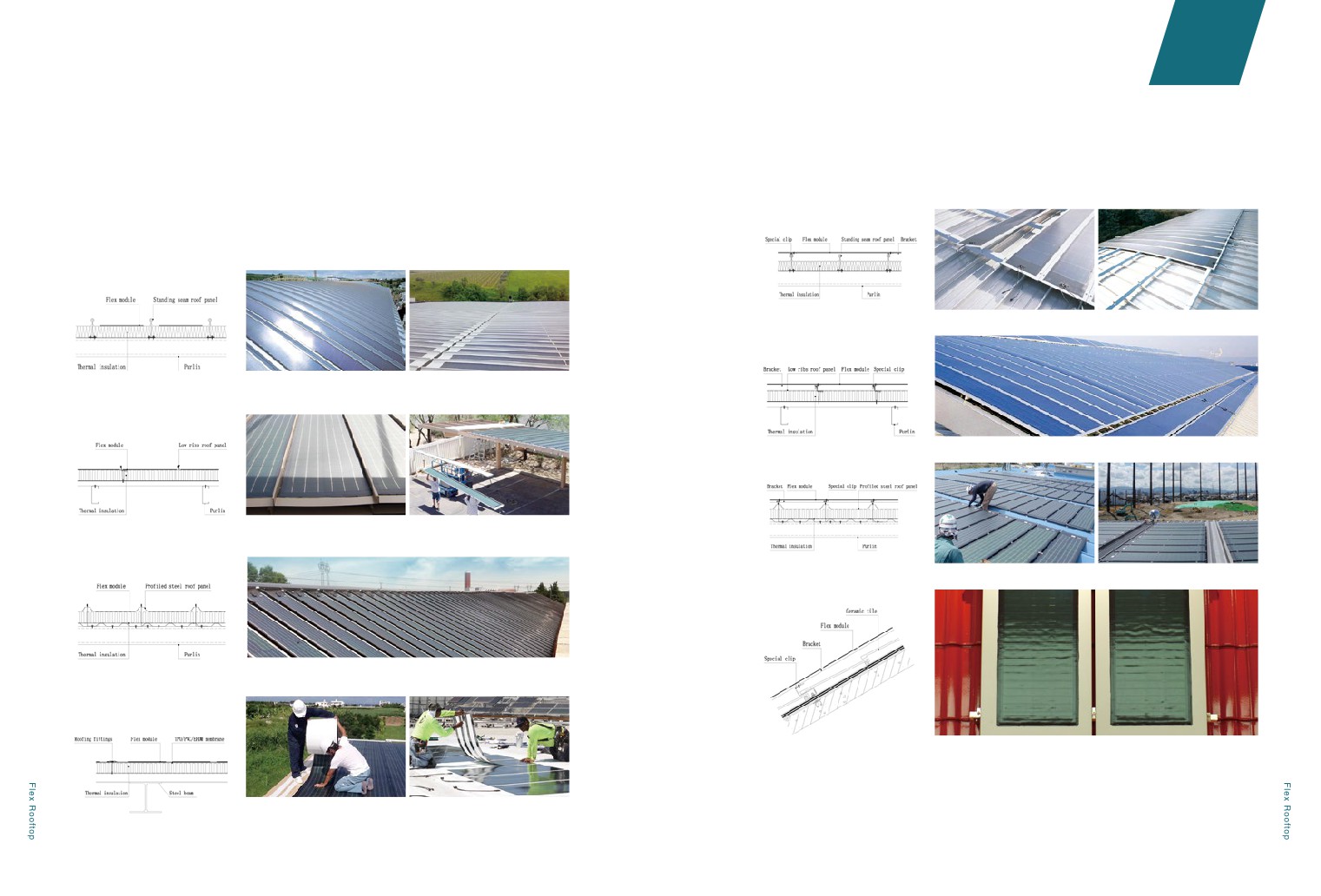

2.4.2

Installation Method

Platform Attachment

Stick flex panels to a platform; then use brackets and clips to fix the platform onto the rooftops.

Apply to the rooftops below:

Direct Adhesion

Peel the release paper off the flex panel and stick the adhesive surface to the rooftops.

1) Standing Seam Rooftop

Apply to the rooftops below:

1) Standing Seam Rooftop

2) Low Ribs Rooftop

2) Low Ribs Rooftop

3) Profiled Steel Rooftop

3) Profiled Steel Rooftop

4) Ceramic Tile Rooftop

4) TPO/PVC/ EPDM Membrane

Rooftop

36

37

Chapter

02

SOLUTIONS

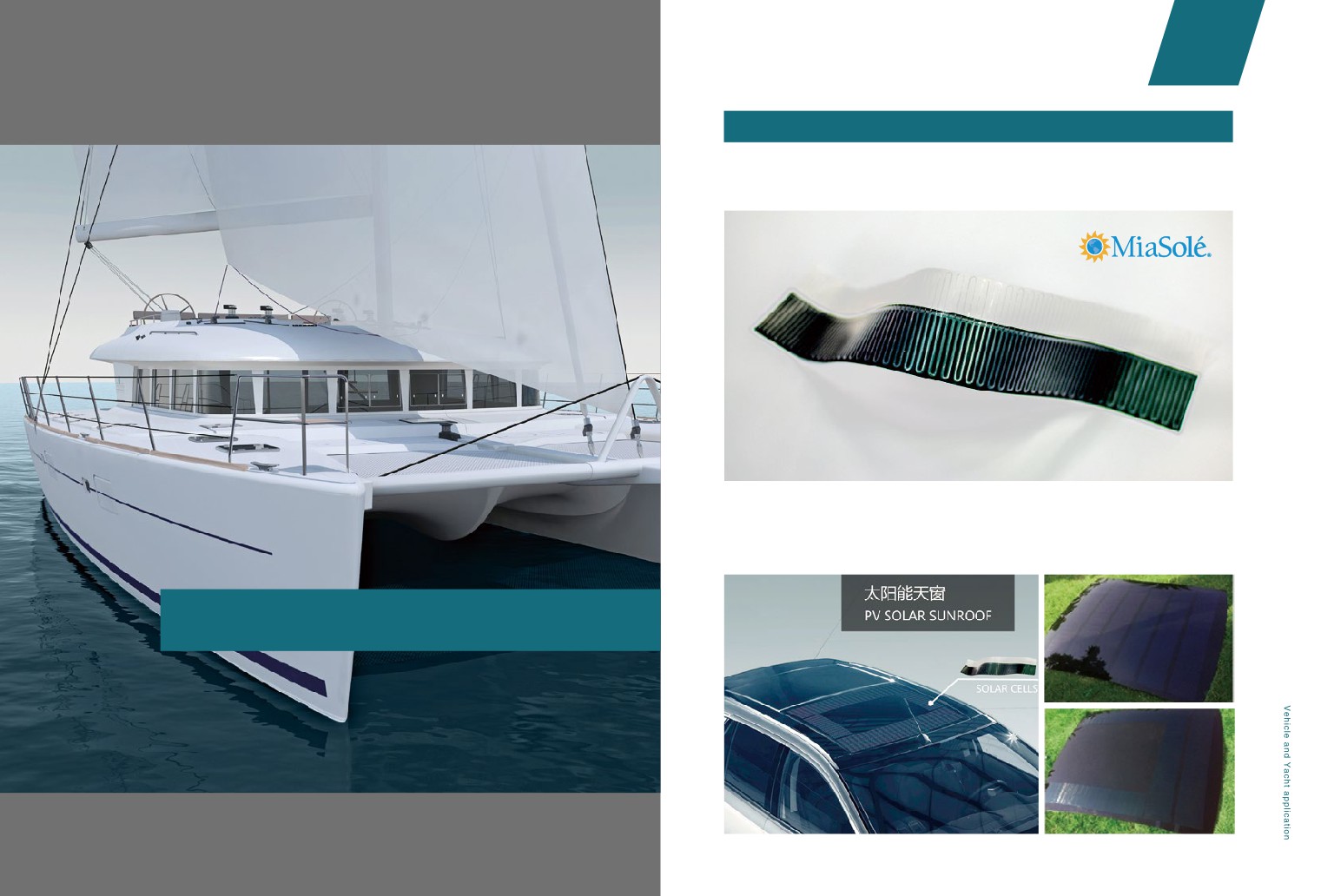

2.5.1

solar sunroof solution

Advantages of CIGS technology

•cell mass production efficiency 16.4% (2014)

•light, flexible, substrate only 50μm

•can be cut and customized

•UltraWire ™ design, positive and negative connection is convenient

PV solar sunroof

2.5

Vehicle and Yacht application

39

Application scenario—ventilation

In summer, the in-car temperature can be very high(70

℃ ) when the vehicle is parked under the

sunshine for some time. Then you need the automatic ventilation system which the solar sunroof can

bring. When parking, the solar sunroof will supply power to ensure air circulation through the ventilation

fan. The in-car temperature can effectively drop to 20

℃ and the surplus power can replenish the

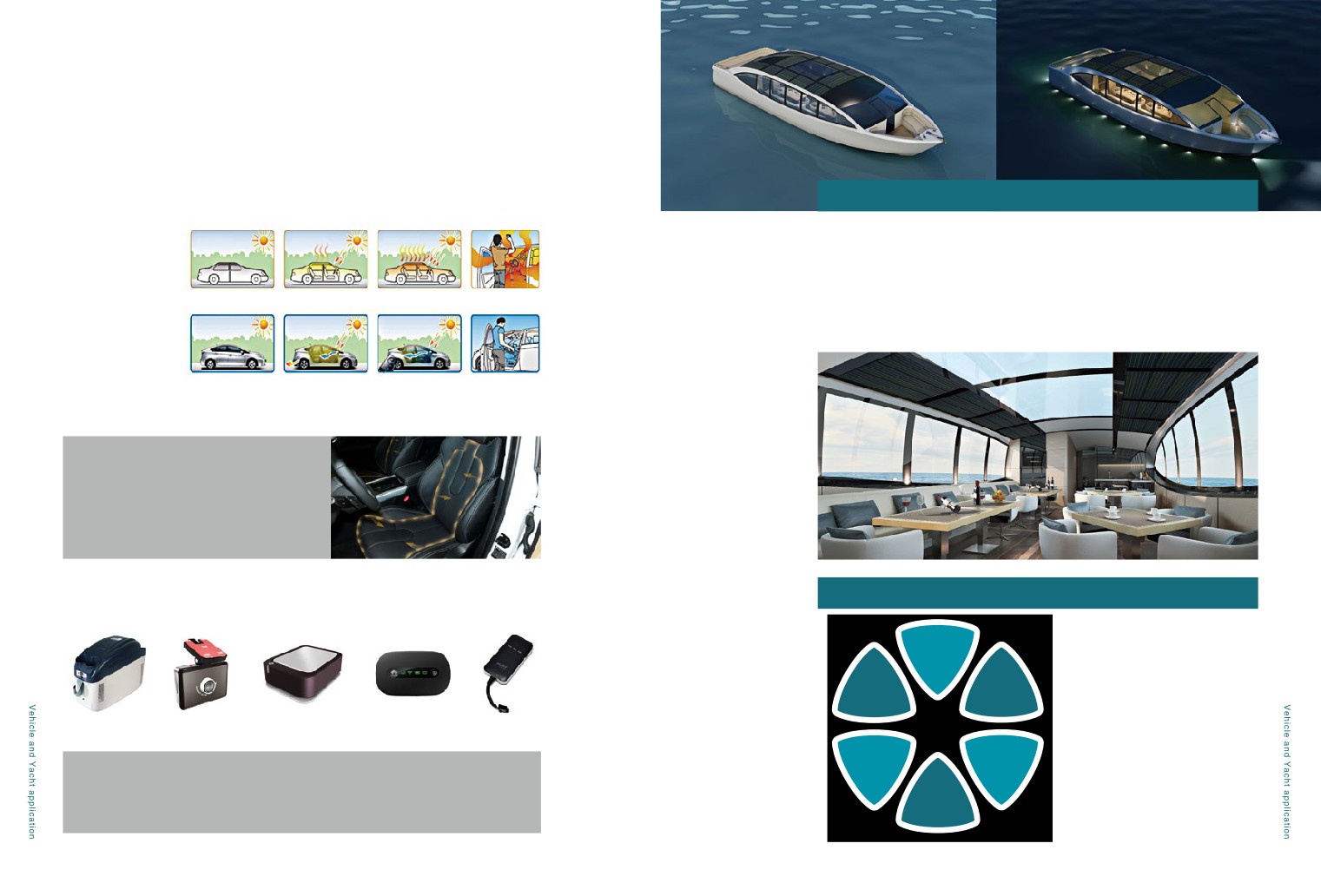

2.5.2

Yacht/ ship application

battery to prolong its service life.

Without solar sunroof

when parking

temperature rises

stuffiness increases

Environmental protection:Solar sightseeing ships benefit the ecological environment and sustainable

development as they produce zero emission and zero pollution.

Economic benefit: Solar vessels reduce the energy consumption leading to lowered operational cost of

the vessels.

Social effect: pure solar yacht can raise concerns of the public about environmental protection and

with solar sunroof

when parking

cooling

establish a good social image.

1、generates energy with solar

2、starts the ventilation system

3、switches on the air conditioner

4、no longer have the stuffy

power

and vents away hot air with solar

with the smart key before driving

feeling when getting in the

power

car

Application scenario—seat heating

In winter, the cold temperature not only leads to the

uncomfortable driving experience, but also tends to

damage the engine. Then you need the seat heating

and car-body preheating functions which the solar

sunroof can bring.

2.5.3

Power solutions for mobile applications

Application scenario—power supply to electronic equipment

Trickle

charge

system

Security

Heating

Application scenarios:

lighting/

Ventilation

power supply

Air

motor homes, bus, cold chain car,

system

Conditioning

insulated truck, urban railway, special

Car fridge

Data recorder

Air cleaner

WIFI

GPS security locator

CIGS

vehicle

Intelligent

Extended

modular

With the development of the automobile industry, electronic devices in cars demand for electricity

range

System solution introduction:

application

increasingly. Solar sunroof can effectively collect solar energy and transform it into other forms of

Cold chain/

include solar panels, installing suite,

energy to supply the air conditioner or battery in the car. Therefore, this system is also suitable for

Heat

preservation

controller, cable

Hybrid Electric Vehicles or Pure Electric Vehicles.

40

41

Chapter

02

SOLUTIONS

· The power generation rate of CIGS cell is high. It can integrate perfectly with car roof thanks to its light

weight, thin shape and flexibility.

· It can prolong the service life of the storage battery by preventing electricity lost.

· It can charge the vehicle navigation system, vehicle traveling data recorder, entertainment system,

digital products, etc.

· When parking in summer, the controller can ventilate the car automatically to clean the air.

2.5.3

Auto parts market application solutions

· Outdoor emergency system.

Product introduction

· It is portable and exquisite so that it is easily packed into the car trunk and suitable for power supply

and emergency relief purposes.

· It is possible to be the vehicle’s standard accessories thanks to its perfect design and power supply

features.

· Its energy storage system supports 5V, 12V, 110V voltage output.

· It can supply lighting and charging (mobile, pad, camera, laptop and so on).

No need for the screw to penetrate the car roof,

Easy to attach, can be well-fitted with a variety of roof shapes

causing no damage to the roof

Product features

Clean energy-----transfer solar energy to electric energy

Environmental protection----- zero carbon emission & zero pollution

High percentage conversion rate-----CIGS solar cell (the world’s highest efficiency)

Portable----- weighs less than 2KG and the size matches all types of trunks

Multi-purpose ----meet different needs of car owners

Expandability----increase panels to meet different power needs

Vehicle can stop at any position, the panels require

Panel installation does not affect the appearance of

no particular installation angle

the vehicle body

42

43

02

Chapter

SOLUTIONS

2.6.1 General View

A Hanergy Household Solar PV system

Level 1 priority: Generate electricity for

household appliances

· Is a mini power station installed on the top of

your private residence, which utilizes thin-film

Solar PV panels absorb the sunlight and

transform it to DC (direct current). The inverter

solar panels to absorb the sun’s energy and

converts DC to AC (alternating current), which

generate it to electricity.

can supply all your household appliances like it

· Can be installed in any places exposed

used to.

to sunlight, such as your roof top, balcony,

Level 2 priority: Surplus energy storage

garden, carport top, etc.

surplus electricity unconsumed by home

· Is a power station that you can own in 2

appliances will be stored in batteries for use at

weeks and can serve you for as long as 25

night or during raining or snowy days.

2.6

Household Solar PV system

years, unremittingly.

· Doesn't just save you money. Thanks to a

Level 3 Priority: Access to the Grid for

Government backed scheme, it earns you

excessive electricity

money too.

When the battery is full, the system will

automatically export the excessive electricity to

the grid and earn additional income.

45

02

Chapter

SOLUTIONS

③ Monitoring

Your solar generation and electricity consumption will be

updated in real time by your monitoring system.

Hanergy monitoring system can enable you to:

1.Obtain the data of generated & saved energy all day

2.6.2

Hanergy Household Solar PV system

long;

2.Get other data, such as your daily contribution in

A Hanergy Household Solar PV system is basically composed of 3 parts:

respect of carbon emission;

3.Be aware of the appropriate time to cleanse your

① Hanergy Thin-Film Solar Panels

system;

Hanergy Thin-film panels (including standard panels, color panels, transparent

4.Know about the breakdown of the system in time.

panels and flexible panels) have outstanding low-light behavior, steady

guaranteed performance, and an attractive visual appearance, making them

A monitoring system:

perfect for homes. The 25 year warranty covers the panels for up to 80% of their

Is easy to use: It can be easily monitored through your

original output.

PC or other mobile devices, whose software/Apps can

be quickly downloaded and installed.

② Inverter and other electrical equipment

Can realize long range control: It incessantly sends

The inverter turns the Direct Current into Alternating Current (AC) so it can be used within the home.

system data to your devices through internet.

Meanwhile, the information can be shared between all

Other electrical equipment such as controller, combiner box, fuse board, etc. can make the system complete and

your indicated devices.

ensure the performance.

Gives excellent performance: It can automatically

Standard Configuration Parameter Table (Using Solibro 115W Panel as example)

generate intuitive histograms from data and can record

failure with its cause.

Common Grid-connected system

Energy storage Grid-connected system

System Capacity

3.45kWp

4.14kWp

5.75kWp

3.45kWp

4.14kWp

5.75kWp

Size & Weight

Controller Size

545x504x149mm

765x504x149mm

Controller Weight

15.5kg

20.5kg

CIGS Moudle Capacity

30

36

50

30

36

50

DC Side

Battery Capacity

N/A

400Ah

600Ah

800Ah

Output at Night

N/A

4.4kWh

5.3kWh

11kWh

Max AC Output Current

13A

16A

25A

13A

16A

25A

3-Phase Mutual

AC Side

Adopted

Adopted

Adopted

Adopted

Adopted

Adopted

Inductor

Isolation Transformer

Adopted

Adopted

Adopted

Adopted

Adopted

Adopted

46

47

Chapter

02

SOLUTIONS

Monitoring system instructions

Hanergy intelligent monitoring system is composed of the local monitoring system and the network remote

monitoring system. The local monitoring system allows you to check the generation data and to set parameters

Saving

through the inverter LED screen display or through your PC (with cable connection to inverter). The network

At the same time, you can save money and resources as well:

remote monitoring system helps you to visit the system’s server through your PC, tablet computer or smart

phones, so as to look over the current, accumulated and statistical data.

• Get free electricity from the sun and save up to 50% on your energy bills

• Decrease your risk of future increases in electricity rates

Hanergy monitoring system displays all the key data of electrical equipment in the terminal of the controller

and upload it to the server. The Hanergy thin-film PV power station owner can get all information, such as the

• Save up to one tonne of carbon per year

hourly output, the daily system efficiency, the battery (if needed) state, self-using power of inverter, uploaded

power, etc.. It greatly helps the owner and the maintenance team to monitor the quality and the efficiency of all

equipment.

Let's take a closer look at why solar is the ultimate feel-good investment:

Hanergy monitoring system unremittingly ensures the maximized interest of the owner.

For 2.88kW system fit for a semi-detached home in Maidstone, Kent, you can make an annual return of£623.

This will help pay back the entire cost of the system in roughly 8 years.

Annual Benefit Breakdown

Feed-in Tariff Income------£367

Export Tariff Income -------£61

Electricity Bill Savings------ £195

= Total Annual Benefit------ £623

% Return on investment:12%

2.6.3

Earning and Saving

Earning

Every year, with a Hanergy solar system you will make money in three distinct ways:

Obtaining “FIT (Feed-In Tariff)”

For every kWh that you produce, whether you use it or not, you can get corresponding revenue called FIT. The

FIT value depends on the government backed scheme.

Obtaining “Sell electricity tariff”

For every excess kWh that you sell to the grid, you will earn additional revenue.

Reduce 50% daily electricity costs

Your solar system will generate free electricity to your household appliances, so you SAVE buying nearly 50%

from your expensive utility each year.

48

49

Chapter

02

SOLUTIONS

1 Grid interconnection

2 System design and budget

Hanergy IKEA Store @ UK

application guidelines

analysis

As a one-stop

6 Perfect after-sales

3 Panels electrical equipment

shop, Hanergy

service

and other accessories provision

provides:

5 Monitoring system and

4 Site support during the construction

data analysis

2.6.4

One-Stop Service

Hanergy Carrefor Store @ Poland

Selecting the Hanergy Household Solar PV System means the procurement of not only a high quality product, but also

2.6.5

Hanergy Stores around the World

Hanergy’s standardized and systemized services.

In order to make it a pleasant experience for the customer to purchase this affordable solar system for your home, Hanergy

Hanergy wants to inspire you and enable you to live a more sustainable life at home and

offers to provide a full range of installation services. We will employ next generation solar technology, create an expert team

help you save money, reduce waste and energy consumption.

and constantly improve our services.

Step 1: Pre-sales advisory service

Step 5 Site operation

Includes: popularization of the use of clean energy,

Includes: equipment transportation, constructors dispatch,

photovoltaic products and system introduction, installation

on site construction, provision of protection measures

procedure explanation, etc...

Step6 Data monitoring

Step 2: Measurement and calculation of roof top

Includes: provision of data monitoring system, immediate

Includes: Load calculation, recording of near shadings,

alert of data exception

professional mounting recommendation

Step 3 System design and budget analysis

Step7 After-sales service

Includes: array design, selecting & matching of electrical

Includes: service manual, quality and performance

equipment, estimation of total expense

guarantee, life-long maintenance

Step 4 Application for grid connection

☆ We provide support if any issues arise with your system.

Hanergy Experience Store @ China

50

☆ Don’t even worry about it. Leave all those application

Over a hundred Hanergy stores are ready to

troubles to the Hanergy expert team!

be opened this year.

02

Chapter

SOLUTIONS

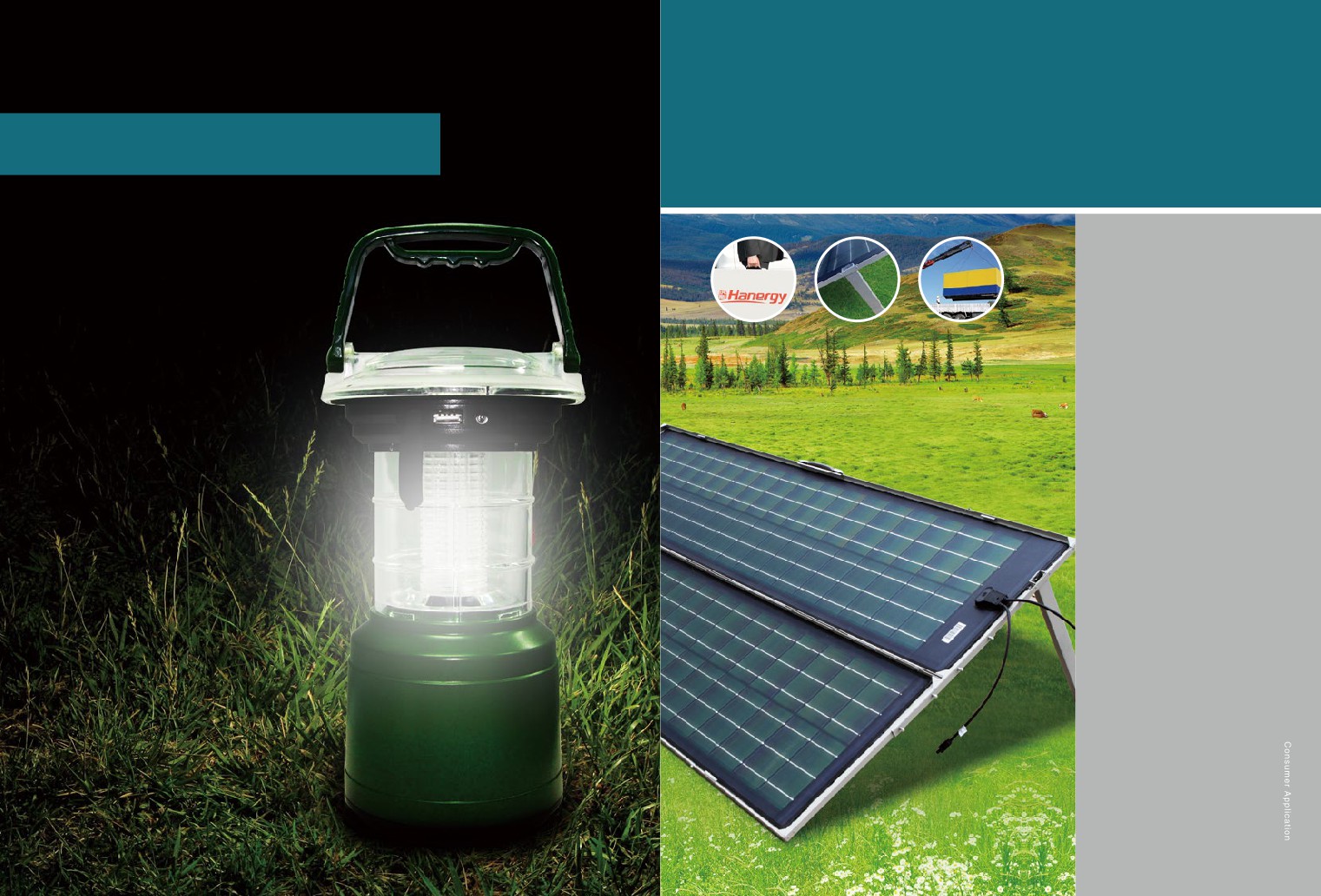

2.7.1 Rapid Deployment System (RDS)

2.7

Consumer Application

The rapid deployment system (RDS) is an emergency power supply solution, which is designed to assist

disaster relief operations around the world, or to provide power to off grid areas on a short/long term

basis.

RDS ADVANTAGES

Light Weight

The system weighs less than 10

tons, convenient for sea, land & air

Super light

30s rapidly pack & deploy

Portable

transportation.

Compact

All system components are fixed & stored

in a 20ft container.

Easy to Pack & Deploy

It takes 5 non-skilled workers less than 3

hours to deploy the whole system.

High Power Output

The theoretical power output is 70 KWH/

sunny day & 12KWH/cloudy day.

Note:

· The system power output varies in

different places.

· The measured power output

· KWH/day ( Sunny, Sep 13th, at

Formula E, Beijing )

·

15KWH/day ( Hazy & Cloudy, Sep

25th, at ERExpo, Beijing )

53

Chapter

02

SOLUTIONS

Off-Grid Locations

Border Post

Solar Module

RDS adopts the cutting-edge thin-film technology - CIGS flexible thin-film solar modules (100W, 2.6KG/piece, by

Controller

Global Solar Energy) to guarantee the rapid & high power generation during the day.

Invert

Battery

The whole system is fixed within a 20 foot container and is easy for rapid transportation & deployment.

The 19.2KW system consists of 192 pieces of flexible thin-film modules, MPPT charging controllers, bi-directional

Battery

inverters, battery storage systems, string boxes & AC distribution cabinet, etc.

Electricity

The emergency power supply solution is specially designed for the below situations:

20ft Container 3D Image

CUSTOMIZATION

Hanergy provides the system customization upon clients’ requests,

which covers:

1. System size

2. Container size & coating

Earthquake Diaster Relief

Remote Areas without Electricity

3. Auxiliary functions: WiFi, radio communication, etc.

Prairies / Pasturing Areas

Island and lslets

54

55

Chapter

02

SOLUTIONS

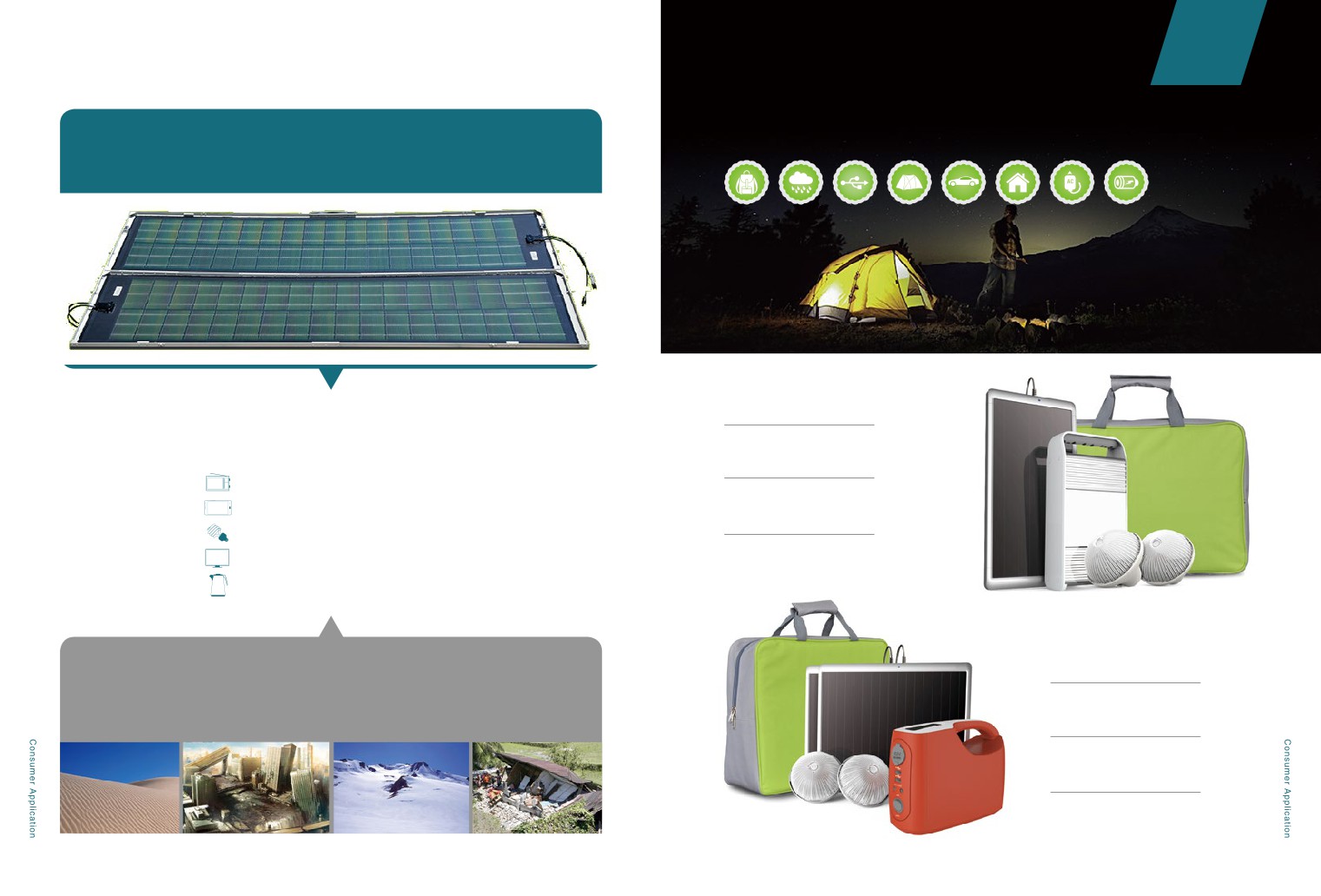

2.7.2 Solar Camping Kit

With the idea of energy-efficiency and environmental protection, solar camping kit is portable, convenient, has long

service life, and ensures you to enjoy outdoor life freely.

It can generate one kilowatt electricity per day!

KP3-033

What can one kilowatt electricity do?

Charging Time by Solar:

20-22 Hours, depending on the sunlight.

One month continuous radio play

Single Lamp Working Time:

200 hours recharge of iPhone 5s

25-27 Hours.

100 hours lighting for 10W energy-saving lamps

10 hours play of 55-inch LCD TV

One hour continuous burning of a 1000W kettle

KP3-105

Where can it be applied?

Earthquake-stricken and remote areas where electricity is lacking,

Charging Time by Solar:

border posts, and any other open areas where electricity is needed

15-17 Hours, depending on the sunlight.

Single Lamp Working Time:

28-30 Hours.

56

57

Chapter

02

SOLUTIONS

CP1 - 060C/E

This solar charger is an appropriate

partner to your outdoor activities. It

could be charged by solar repeatedly

in many flexible ways, such as

hanging on knapsacks or adsorbed on

windows, because it is equipped with

a sucker and a hook. Besides, it has a

series of connectors for your different

electronics.

Charging Time by Solar:

60-62 Hours, depending on the

sunlight.

Charging Time by Adapter: 4-5 Hours.

Lamp Working Time: 40 Hours.

Battery Specification: 3.7V/2400Ah.

Charging Time for iPhone: 4 Hours.

LP2-325A

This is a solar camping light and

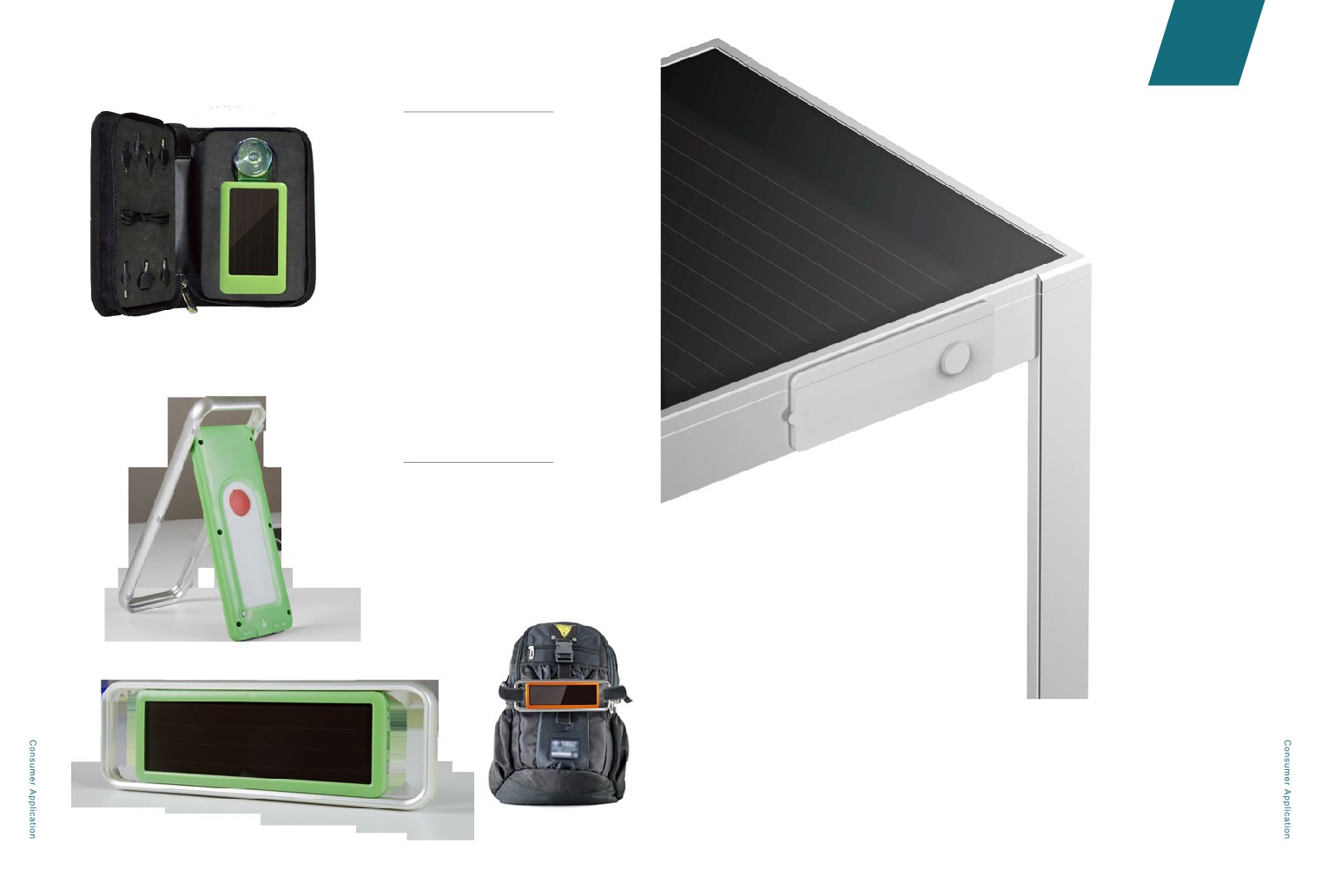

2.7.3 Solar Smart

charger. It is appropriate to outdoor

lighting and mobile phone charging.

Table

Charging Time by Solar:

28-30 Hours, depending on the

sunlight.

T-S-A-62M-07

Lamp Working Time: 9-11 Hours.

Solar smart table stores the energy into integrated

battery. You may charge your electronics by

connecting USB on the table. It provides you more

convenient power supply solution outdoors.

Coffee Table

Size:661mm×647mm×736mm

Built-in batter

Charge 10 pieces of iPhone (3 hours/piece)

Charge 2 pieces of iPad (8 hours/piece)

58

59

02

Chapter

SOLUTIONS

6.5W Solar Charging Bag

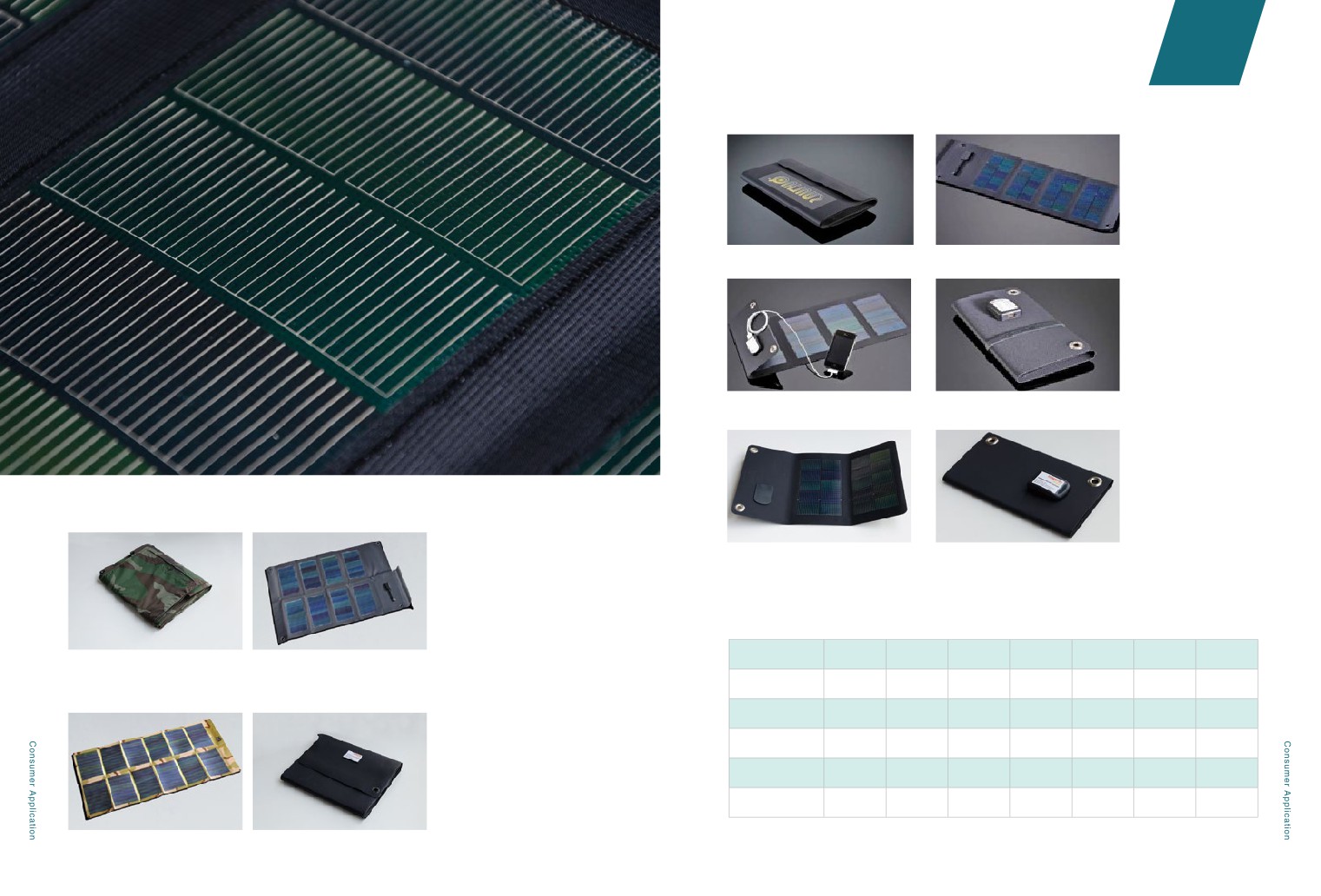

2.7.4 Flexible Solar Charging Bag

4W Solar Charging Bag

2W Solar Charging Bag

30W Solar Charging Bag

12W Solar Charging Bag

Product Specification

Flexible Solar

2W

4W

6.5W

12W

25W

30W

62W

Charging Bag

62W Solar Charging Bag

25W Solar Charging Bag

Voltage

5V

5V

15V

15V

16.5V

18.8V

20V

Current

400mA

800mA

433mA

800mA

1500mA

1600mA

3100mA

Open Size (cm)

35.6 x 22.9

61.0 x 22.9

73.6 x 22.9

73.6 x 45.7

104.8 x 54.6

111.8 x 53.3

133.3 x 76.2

Folding Size (cm)

22.9 x 12.7

22.9 x 12.7

22.9 x 12.7

22.9 x 12.7

26.7 x 21.6

26.7 x 21.6

36.8 x 21.6

Weigh(g)

113

179

198

312

737

907

1451

60

61

REFERENCES

3.1

Utility Scale

3.2

Distributed generation

3.3

BIPV

3.4

Flex Rooftop

3.5

Vehicle and Yacht application

03

Chapter

REFERENCES

3.1

Utility Scale

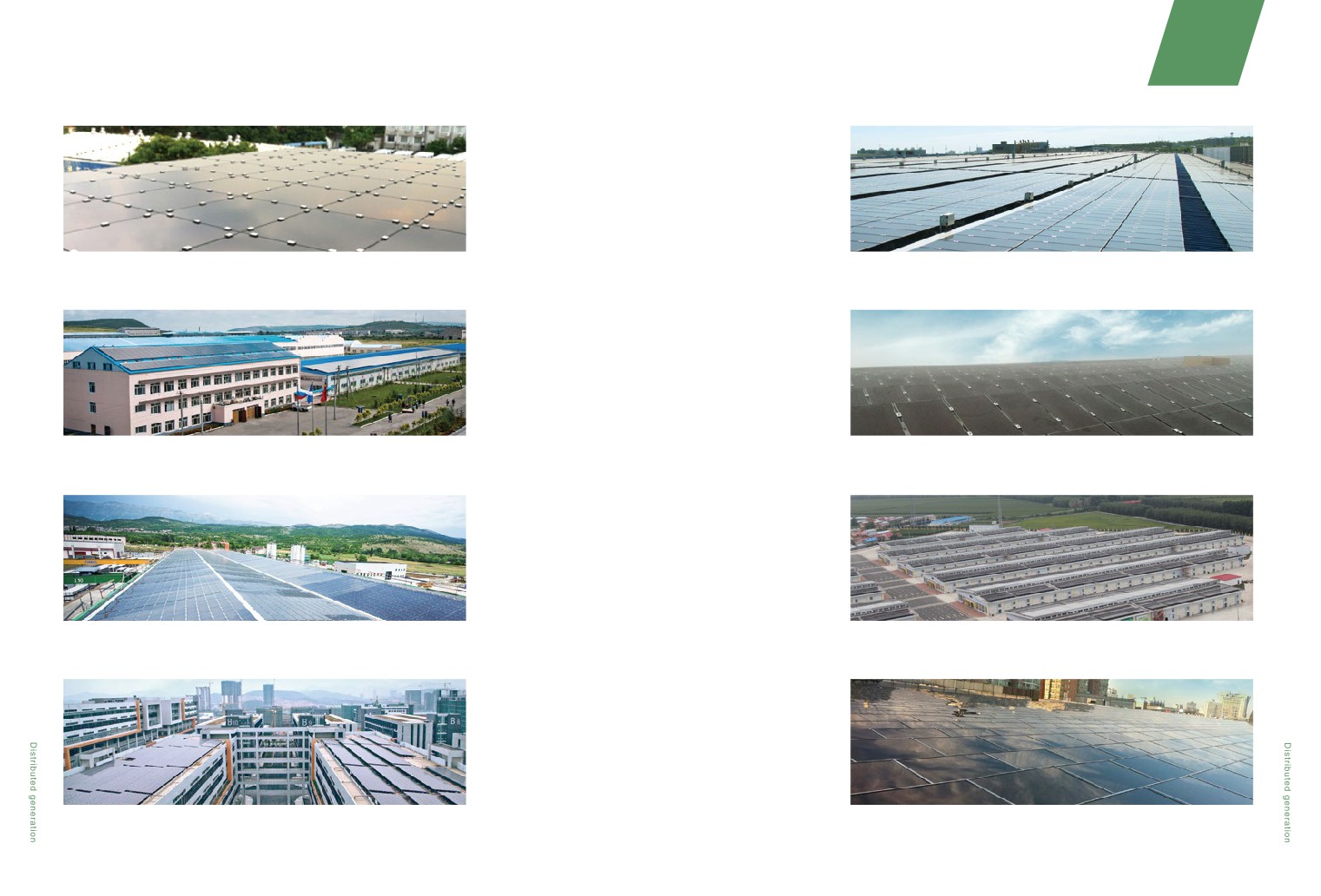

Qinghai Hainan prefecture thin-film ground power generation project (installed capacity: 150MWP /

amorphous silicon thin-film panels / phase one (50MWP) was completed in 2012)

Greek thin-film ground power generation project (installed capacity: 4MWP / amorphous silicon thin-

film panels / completed in 2012)

Ningxia Wuzhong thin-film ground power generation project (installed capacity: 20MWP / amorphous

silicon thin-film panels / completed in 2012)

65

03

Chapter

REFERENCES

Guangdong Heyuan Hanergy Golden Sun thin-film power generation project (installed

capacity: 5.18MWP / amorphous silicon thin-film panels / completed in 2012)

Xiangyang roofing thin-film power generation project (installed capacity: 10MWP /

amorphous silicon thin-film panels / completed in 2014)

Nongfu Spring Water Co., Ltd. Guangdong Wanluhu thin-film power generation project

(installed capacity: 4.82MWP / amorphous silicon thin-film panels / completed in 2013)

3.2

Distributed generation

German Thalheim factory roofing thin-film Solibro power generation project (installed capacity:

1.3MWP / copper indium gallium selenide panels / completed in 2012)

67

03

Chapter

REFERENCES

Honda thin-film power generation project (installed capacity: 17MWP / amorphous silicon

Haikou Hanergy thin-film power generation project (installed capacity: 3MWP / completed

thin-film panels)

in 2013)

Russia Ussuriysk thin-film solar energy roofing power generation project (installed

Hanergy Yucheng thin-film power generation project (installed capacity: 3MWP /

capacity: 100KWP / 2012 for completion)

completed in 2013)

L'Aquila, Italy roofing thin-film power generation project (installed capacity: 837KWP /

Hanergy Heilongjiang Shuangcheng thin-film solar power project (installed capacity:

amorphous silicon thin-film panels / completed in 2012)

5.14MWP / completed in 2014)

Guangzhou accelerator thin-film power project (connected to the Grid in 2013)

Thin-film rooftop solar power project for IKEA stores in Tianjin (installed capacity:

616KWP / completed in 2014)

68

69

03

Chapter

REFERENCES

Guangdong Hanergy BIPV curtain wall project

Jiangsu Wujin Hanergy BIPV curtain wall project

Turpan BIPV curtain wall project

3.3

BIPV

Shandong Yucheng Hanergy BIPV curtain wall project

71

03

Chapter

REFERENCES

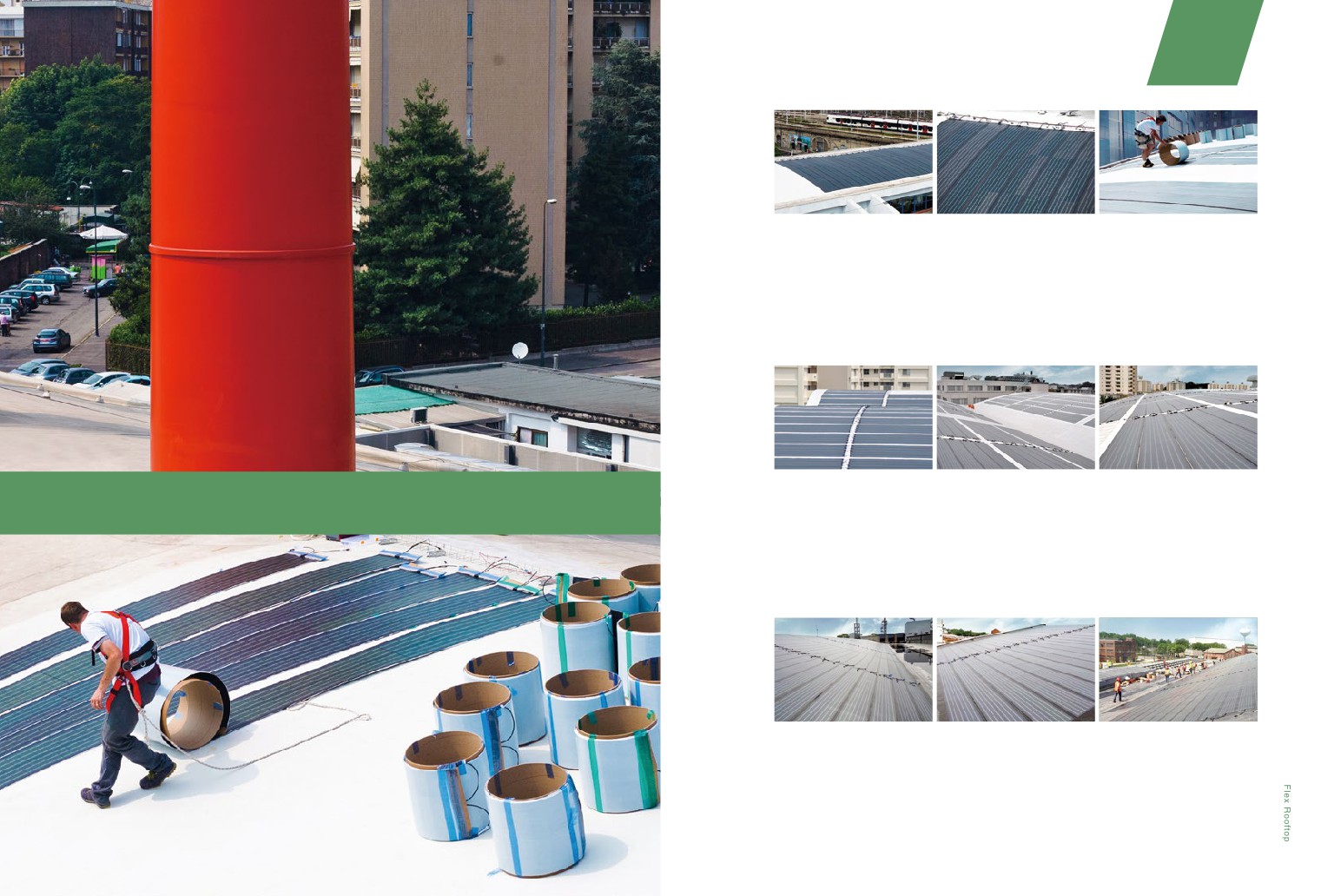

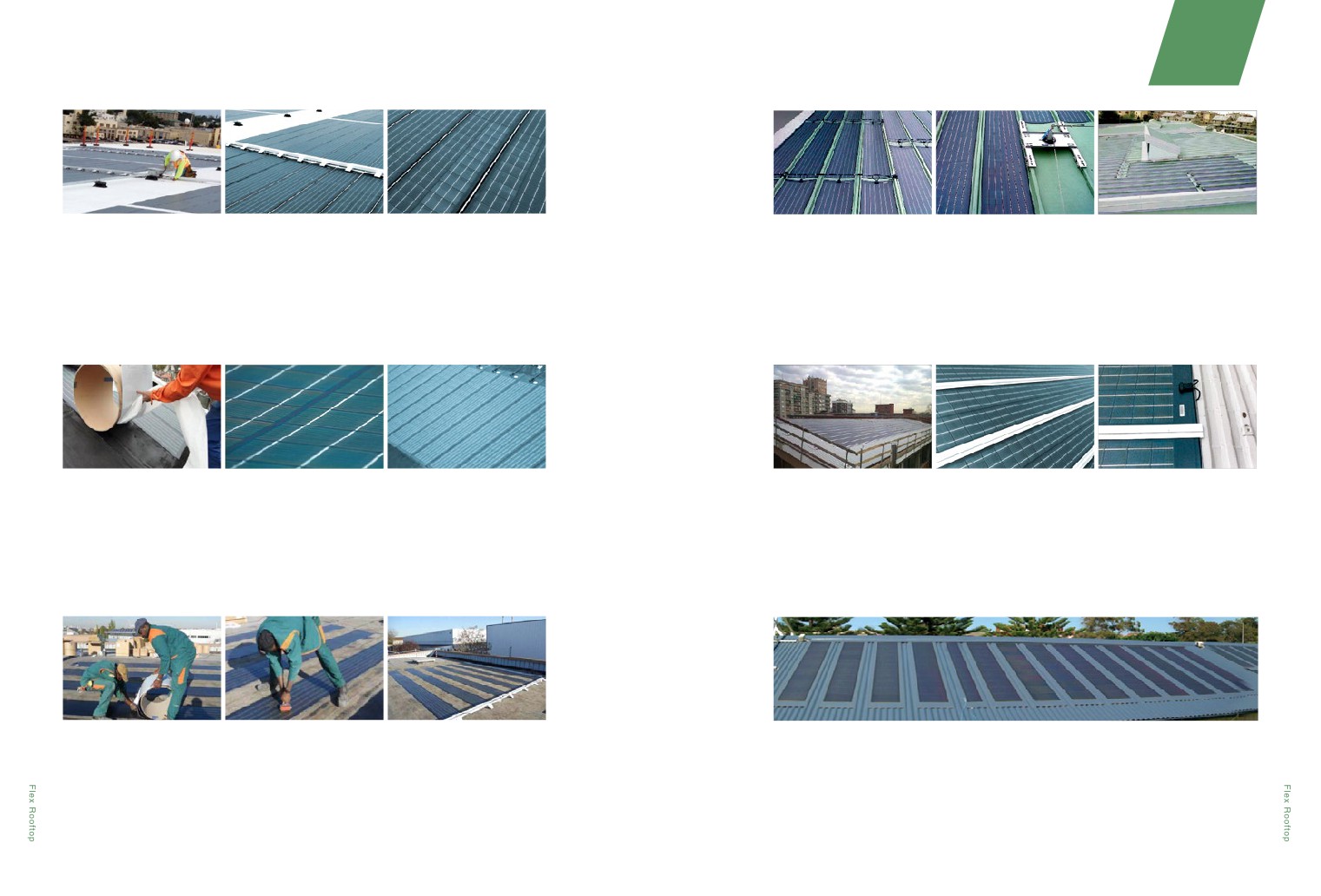

Milan, Italy

• Installation: June, 2011

• Modules:300W PowerFLEX ™ 6

• Power:19.8kWp

• Roofing Material: TPO membrane

• Installation Method: Direct adhesion

Yokosuka, Japan

• Installation: April, 2012

3.4

Flex Rooftop

• Modules:275W PowerFLEX ™ 6

• Power:400kWp

• Roofing Material: TPO membrane

• Installation Method: Direct adhesion

New Jersey, USA

• Installation: May, 2012

• Modules:275W PowerFLEX ™ 6

• Power:350kWp

• Roofing Material: EPDM membrane

• Installation Method: Direct adhesion

73

03

Chapter

REFERENCES

Hawaii, USA

• Installation: October, 2011

Italy

• Installation: September, 2011

• Modules:250W PowerFLEX ™ 6

• Modules:275W PowerFLEX ™ 6

• Power:100kWp

• Power:15kWp

• Roofing Material: Elastomeric coating

• Roofing Material: Standing Seam Metal

• Installation Method: Direct adhesion

• Installation Method: Direct adhesion

Zaandam, Netherlands

• Installation: October, 2011

Milan, Italy

• Installation: December, 2011

• Modules:90W PowerFLEX ™ 2

• Modules:250/275W PowerFLEX ™ 6

• Power:90kWp

• Power:70kWp

• Roofing Material: EPDM membrane

• Roofing Material: Profiled Metal

• Installation Method: Direct adhesion

• Installation Method: Platform attachment

Paris, France

• Installation: November, 2011

Sydney, Australia

• Installation: January, 2013

• Modules:275W PowerFLEX ™ 6

• Modules:70W FLEX-01N

• Power:5kWp

• Power:1.7kWp

• Roofing Material: Modified Bitumen

• Roofing Material: Profiled Metal

• Installation Method: Direct adhesion

• Installation Method: Platform attachment

74

75

03

Chapter

REFERENCES

Flexible panels applied to trucks / containers / refrigerated trucks

Flexible panels applied to RV market

Flexible panels applied to traveling vehicles and ships

3.5

Vehicle and yacht applications

77